Machining centers: the next evolution in the furniture industry

January 29, 2024

The furniture industry has undergone a significant revolution in recent years, driven by the introduction of advanced technologies. In this scenario, machining centers stand out as fundamental elements to improve production and increase the quality of manufactured furniture. The practicality offered by these machines has proven to be crucial in facing the sector's contemporary challenges.

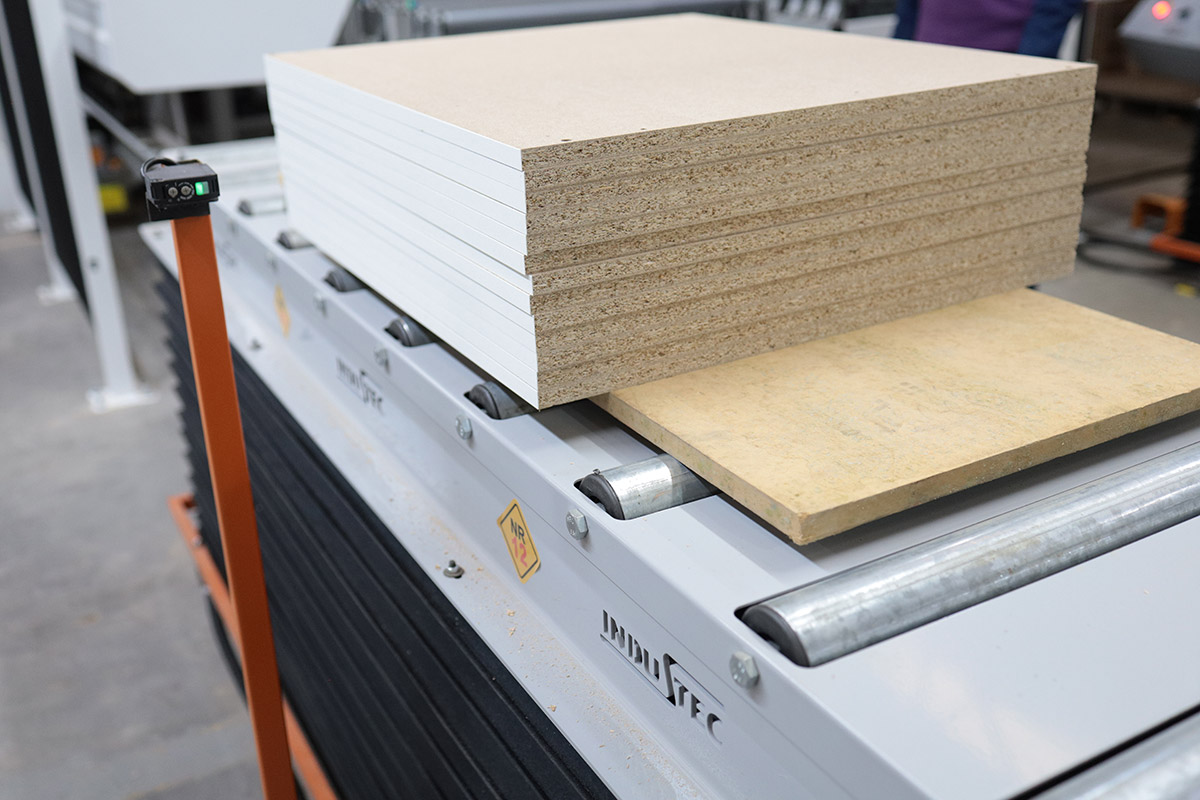

Machining centers are multifunctional machines that integrate several machining operations into a single piece of equipment. In the furniture industry, this means they can perform tasks such as cutting, drilling and milling, providing unique versatility in the manufacturing process. This characteristic allows the production of complex and detailed pieces with high precision, something essential to meet the demands for increasingly sophisticated and personalized furniture.

The practicality offered by machining centers is intrinsically linked to automation and advanced programming. With the ability to process a variety of materials, from wood to composite materials, these machines ensure efficient and cost-effective production. Furthermore, automation reduces dependence on intensive labor, minimizing errors and increasing consistency in production.

Another point to highlight is the optimization of production time. Machining centers operate at high speeds, performing multiple operations simultaneously. This results in shorter production cycles, enabling on-time product delivery and increasing the factory's total production capacity.

On top of the latest developments in this market, Sellmaq's list of suppliers includes the expertise of machines from the Italian brand Bacci. The Artist line, known for being the brand's most versatile, has five axes and independent working tables, enabling the production of different pieces with the most varied materials.