Why do I need 5-axis technology?

Why do I need 5-axis technology?

My production process has many steps, increasing production time and the possibility of error;

I have difficulty standardizing the machining of my products;

My portfolio cannot keep up with design trends and shapes, due to limitations in production processes;

My product requires precision machining processes to guarantee the final product;

I need to increase my productivity.

If you have any of these problems, talk to us!

05 Axis Machining Center

Prices starting atUSD 145.000,00*

* Check shipping conditions

Why choose the 05-Axis Machining Center?

Reduction in production time: performs Cutting, Drilling and milling of parts in a single process;

Reduction of production errors: High level of precision in each operation;

Guarantee of results standardization;

Enables flexibility in the Portfolio, development of new designs and shapes;

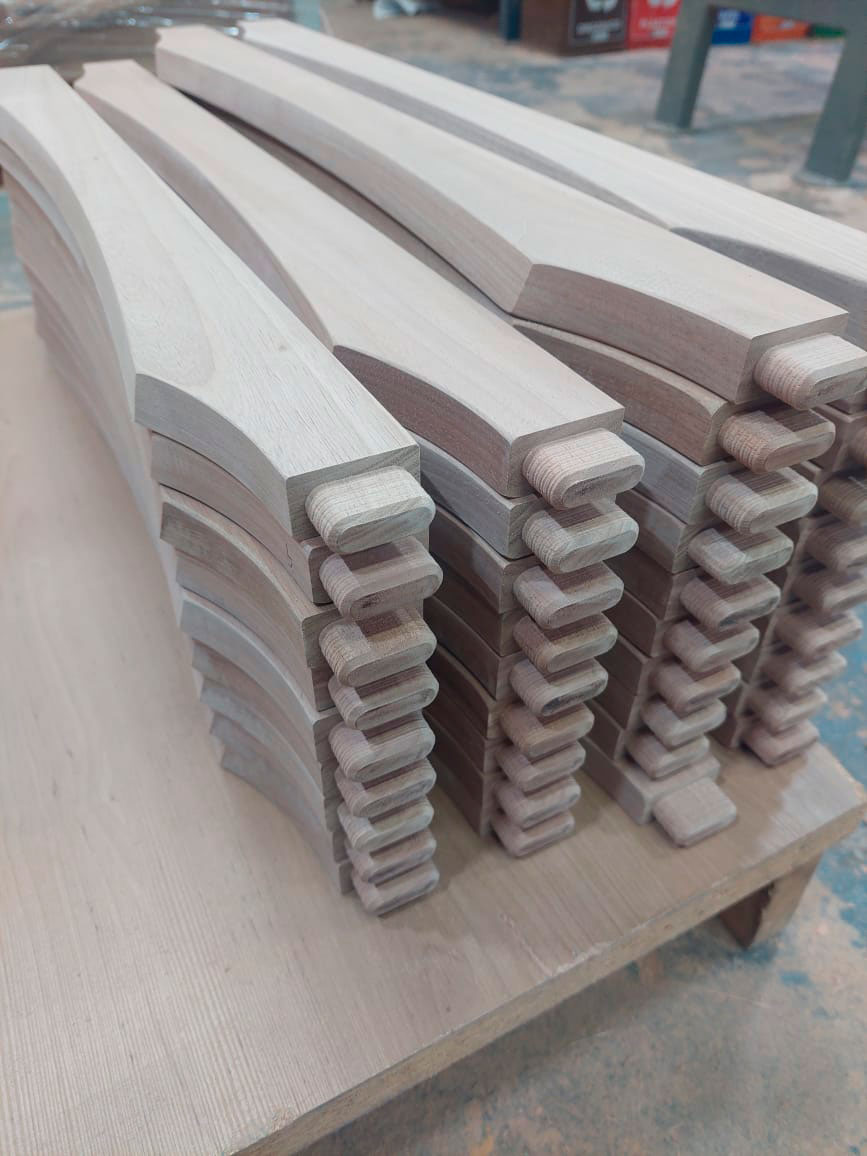

Works on pieces of any type: flat, curved or organic;

Robust structure and high working speed;

Discover the 3 pillars of quality of Bacci's Machining Center

1) Standardization

Ensuring the same level of quality with each delivery is essential to consolidate your brand in the market. Bacci's machines guarantee standardization of results, whether in flat, curved or organic pieces.

2) Productivity

The machines range from machining individual parts (components) to complex machining using axis interpolation. This 5-axis process optimizes several production processes, reducing factory production time.

3) Precision

Bacci's machining center offers the guarantee of precision in each process, operating in segments where this aspect is crucial for the correct functioning/application of the product.

Bacci's machining center is ideal for those looking to standardize their results with precision and quality, adding value to the final product.

In addition to offering versatility to processes by optimizing several steps in a single process, the equipment has wide application and can operate in different segments.

Doors and windows

Tables

Chairs

Coffins

Plastic and plexiglas

Molds and molding

Guns

Other machines

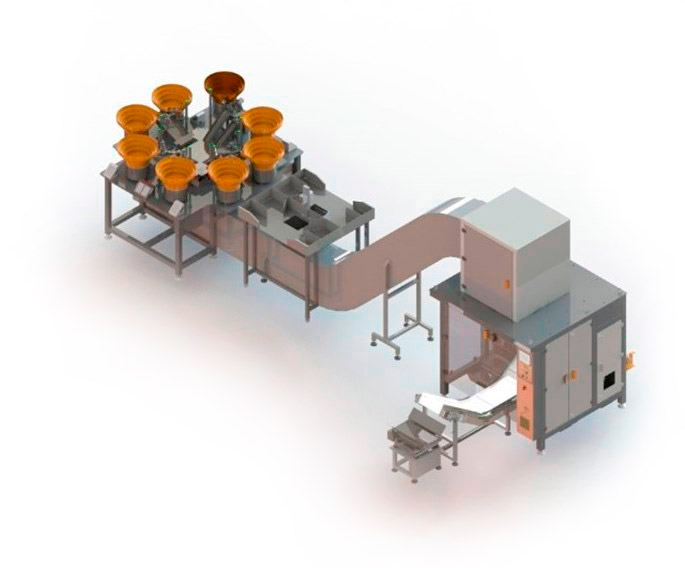

CE-01 counting and packaging machine

CE-02 counting and packaging machine

CE-01 Mini counting and packaging machine

Heat-shrinkable film packaging machine

Automatic orbital Stretch film wrapping machine

Semiautomatic orbital Stretch film wrapping machine ESJ 900

Semiautomatic orbital Stretch film wrapping machine ESJ 1200

Semiautomatic orbital Stretch film wrapping machine ESJ 1600

Semiautomatic orbital Stretch film wrapping machine ESJ 2000

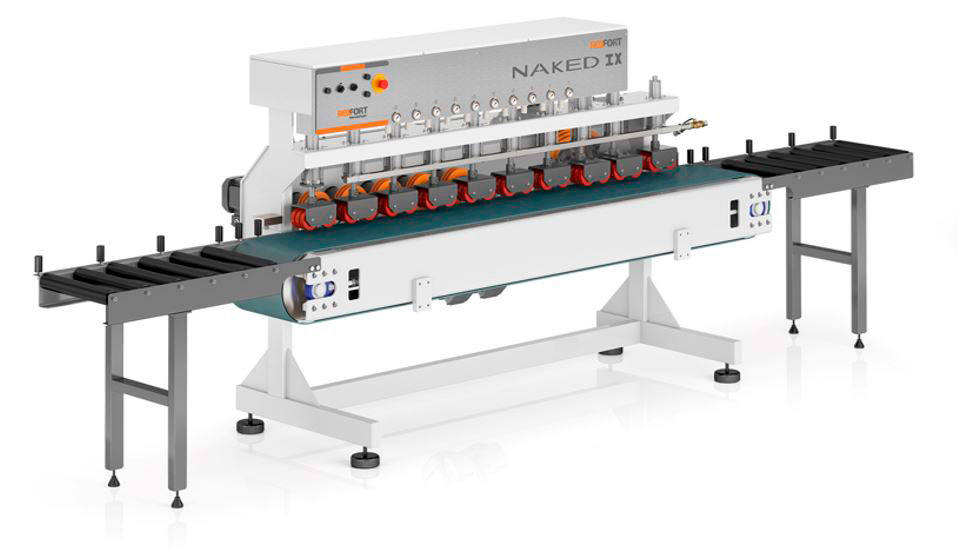

Edge polisher Naked

Cirux bridge Saw

Oblicus 45º Cutting Saw

F400-CS Drilling Machine

F400-T Drilling Machine

F601 drilling machine

05 Axis Machining Center