Why do I need this machine?

Why do I need this machine?

I need to modernize my packaging system;

Difficulty in standardizing my packaging;

High consumption of materials in the packaging of my product;

High rate of damaged items due to transport damage;

Complaints about scratched parts;

Low productivity due to manual processes;

Ergonomic failures in the packaging processes.

If you have any of these problems, talk to us!

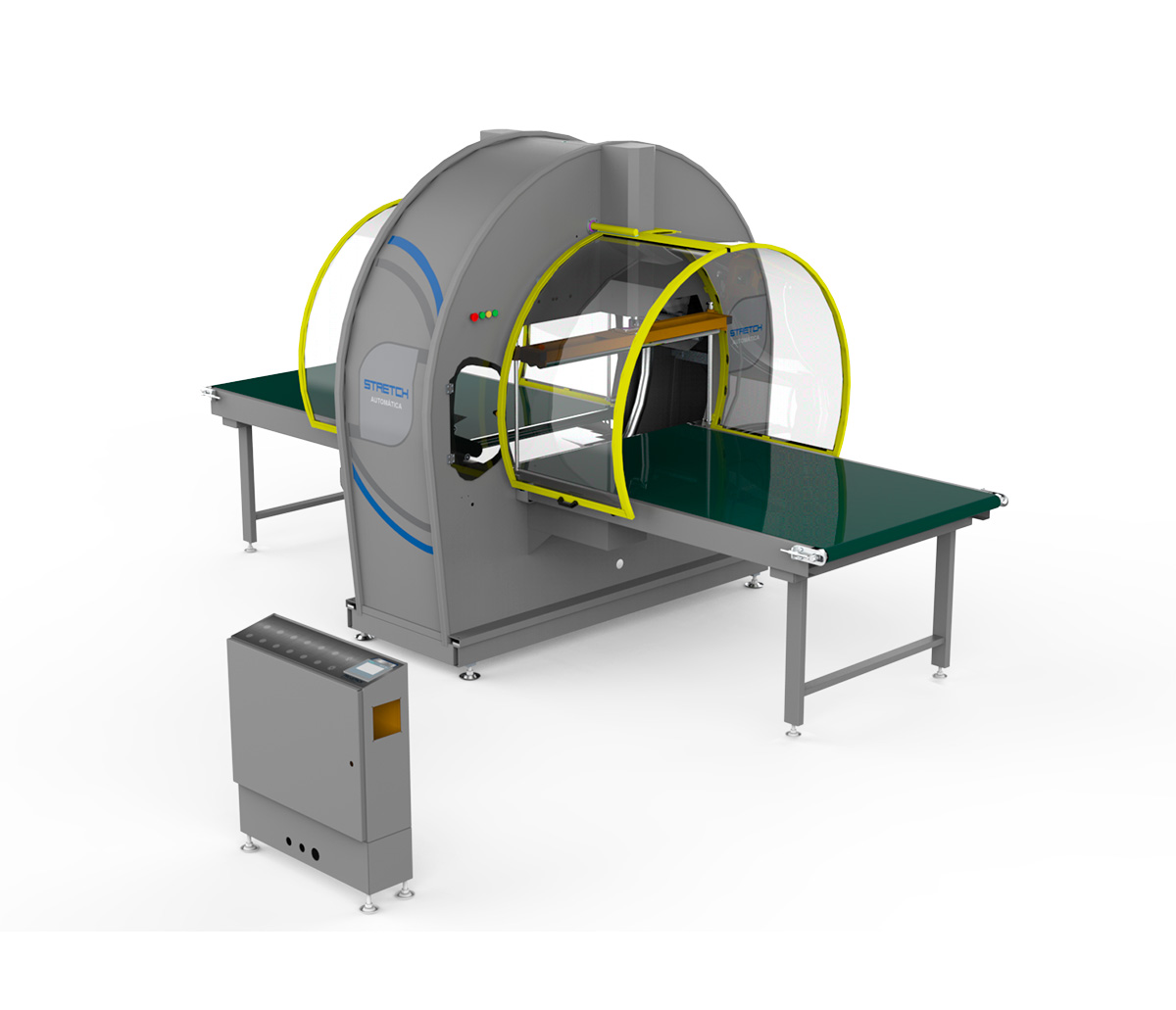

Automatic orbital Stretch film wrapping machine

Prices starting atUSD 32.160,00*

* Check shipping conditions

Product manufactured in accordance with safety standards

1-year warranty

100% Brazilian manufacturing

Excellent wrapping of the parts

Packaging with or without additional protection

Ideal for disassembled products

Higher productivity

Why choose the Automatic Stretch?

Ideal for disassembled products;

Excellent compression of the parts;

Intuitive MMI;

Reduction of material waste;

Production of up to 5 packages per minute*

Applicable to various segments.

*1800mm-long packages

Product manufactured in accordance with safety standards

1-year warranty

100% Brazilian manufacturing

Excellent wrapping of the parts

Packaging with or without additional protection

Ideal for disassembled products

Higher productivity

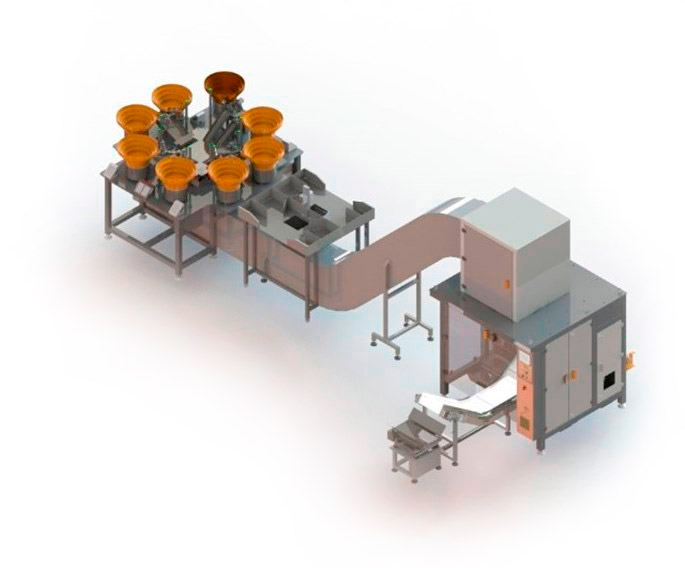

The Automatic Stretch is ideal for packaging disassembled products from various segments.

Its process offers excellent compression, reducing damage problems caused by moving the parts.

Frames

Logistics

Metallurgical

Wood industry

Profiles and Aluminium

Furniture

Other segments

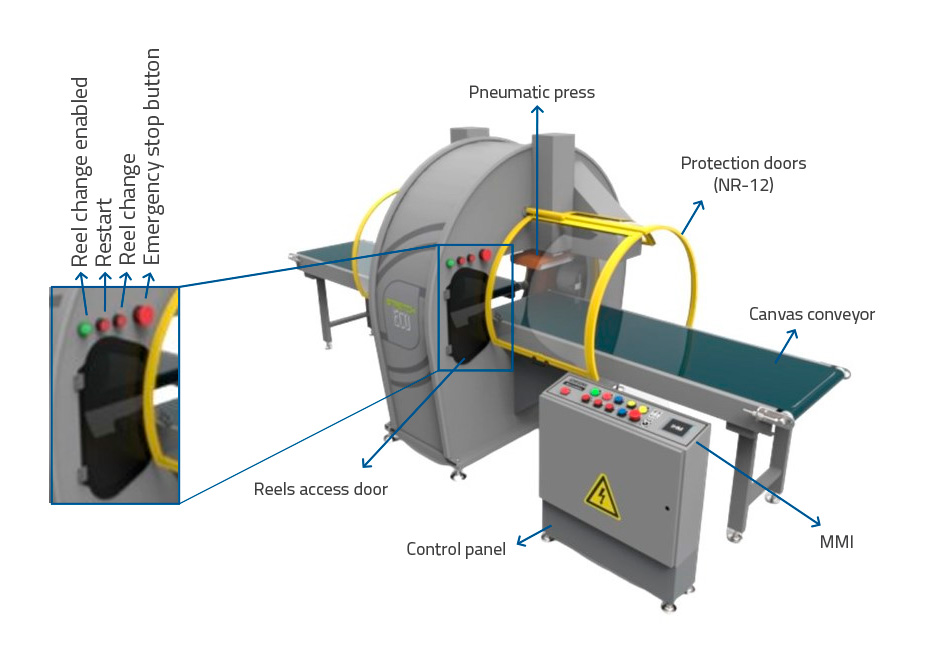

Technological highlights

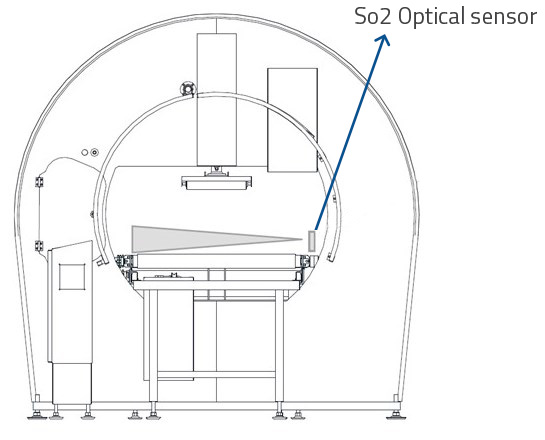

The parts are fed onto a canvas conveyor at the entrance of the machine and are automatically moved. When entering the ring, the So2 optical sensor communicates the presence of the material to be packed, lowers the upper presses to stabilize the parts then starts the packaging cycle.

The parts move along the conveyor while they are wrapped by the stretch film and at the end of the cycle, the film is automatically cut. This way, the machine is ready to package the next parts.

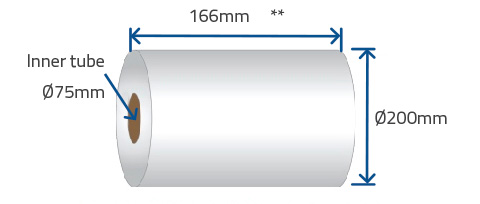

The machine works with reels of 166mm wide, 200mm in diameter and inner tube of 75mm;

It operates with one (01) reel placed in the ring.

Canvas conveyor at the entrance and exit of the machine in order to maintain a constant advance of the parts, avoiding the operator’s physical effort and problems with the misalignment of the parts;

Pneumatic presses, at the entrance and at the exit of the ring, in order to keep the parts stable while they are wrapped by the film;

Frequency inverter on the conveyors to change the advance speed and the adjustment of the film's wrapping on the part.

Automatic control for the start and for the end of the packaging cycle, regardless of the dimensions of the parts, with the possibility of changing the turns in the HMI installed on the control panel.

Potentiometer on the panel to control the speed of the conveyors.

Automatic film cutting system pneumatically activated.

The machine uses reels of:

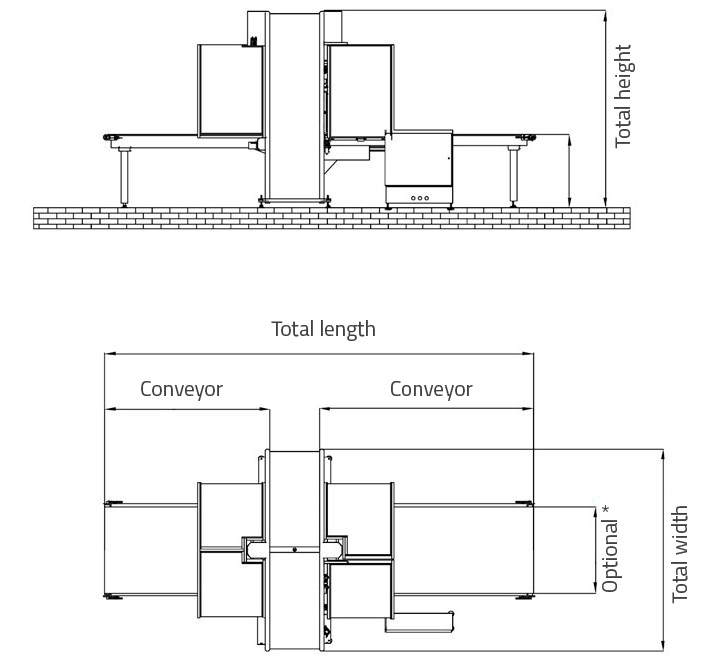

Equipment dimensions

*Optional: Support for disassembled cardboard boxes

| Dimensions (layout) | Option 1 | Option 2 | Option 3 |

|---|---|---|---|

| Width (mm) | 1855 | 2055 | 2255 |

| Length (mm) | 4255 | 4255 | 4255 |

| Length with optional* | 5665 | 5665 | 5665 |

*Optional: Support for disassembled cardboard boxes

Packaging and delivery

Complete Automatic Stretch for export

Other machines

CE-01 counting and packaging machine

CE-02 counting and packaging machine

CE-01 Mini counting and packaging machine

Heat-shrinkable film packaging machine

Automatic orbital Stretch film wrapping machine

Semiautomatic orbital Stretch film wrapping machine ESJ 900

Semiautomatic orbital Stretch film wrapping machine ESJ 1200

Semiautomatic orbital Stretch film wrapping machine ESJ 1600

Semiautomatic orbital Stretch film wrapping machine ESJ 2000

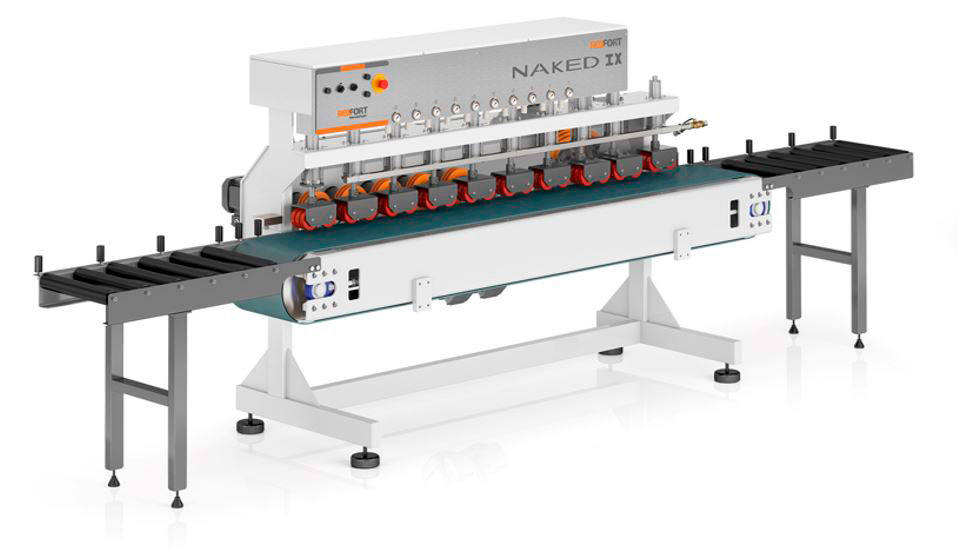

Edge polisher Naked

Cirux bridge Saw

Oblicus 45º Cutting Saw

F400-CS Drilling Machine

F400-T Drilling Machine

F601 drilling machine

05 Axis Machining Center