Why do I need this machine?

Why do I need this machine?

Eliminate manual and repetitive processes;

Reduce labor costs;

I want to automate the unloading process of the multiple drilling line;

I seek to optimize processes in the production line;

Reduce the risk of accidents caused by handling parts.

If you have any of these problems, talk to us!

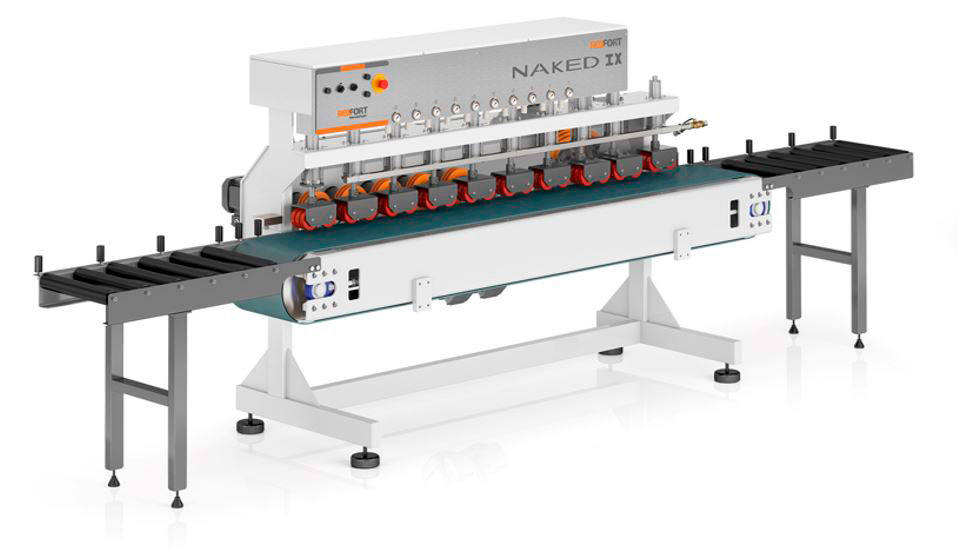

Automatic Unloader for Multiple Machines

Prices starting atUSD 28.490,00*

* Check shipping conditions

Fábricação 100% brasileira

Better ergonomics

Quick setup

Touch Screen Panel

Why choose the automatic unloader for drilling machines?

Fully automatic system with sensors and encoder;

Movement by linear guides;

Table base with rollers driven by belt and motor;

Electric system by PLC (programmable logic control);

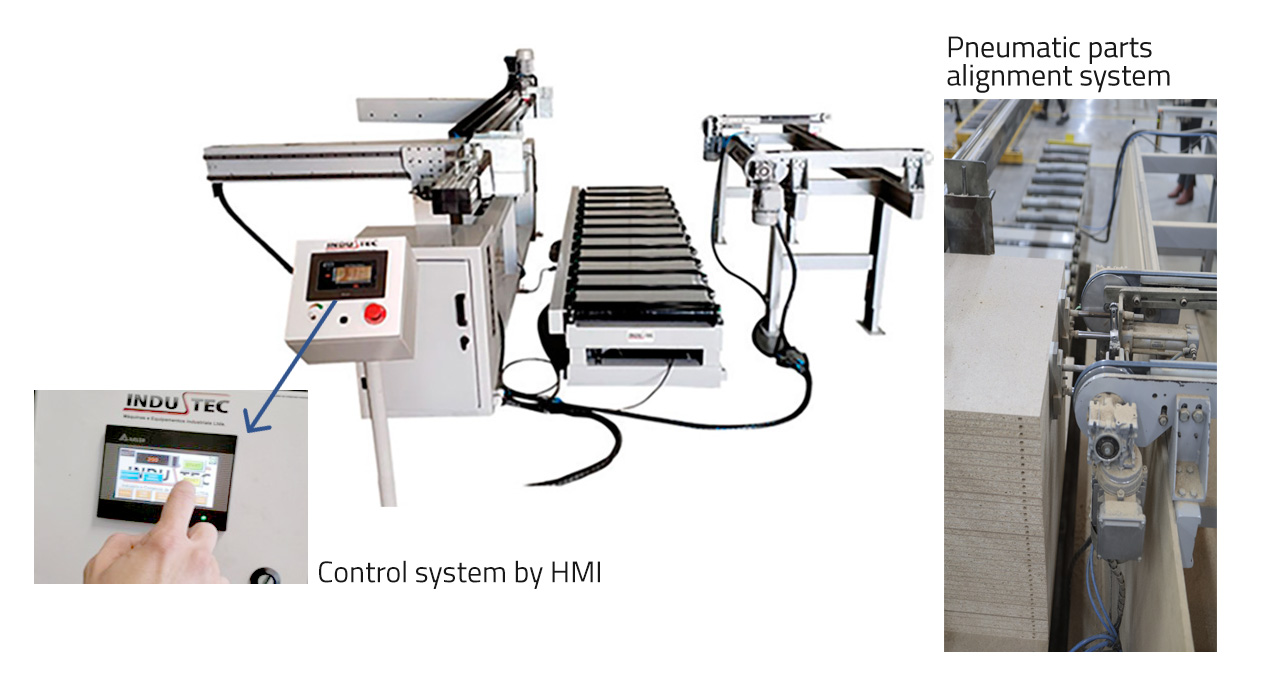

Control system by HMI;

Part alignment system, through pneumatic cylinder;

Pre-conveyor system at the drilling machine’s outlet to prevent parts from getting stuck;

Automatic part width adjustment system by encoder.

Fábricação 100% brasileira

Better ergonomics

Quick setup

Touch Screen Panel

Furniture

Technological highlights

The automatic unloader for drilling machines is the ideal option for automating the steps involved in moving parts that leave the drilling line ready.

The HMI control system, automatic width and length adjustment according to the size of the part to be unloaded, the part counting system and pneumatic aligners are some of the features that make the process much more efficient.

The process begins by including the dimensions of the part in the HMI, the equipment automatically adjusts to the dimensions that were previously referenced, as soon as the drill releases the finished part, it "slides" to the unloader’s table and the parts are stacked and adjusted in the stack with the aligner that is moved by pneumatic cylinders, the height of the table is automatically adjusted as new parts are stacked.

The reading of the quantity of parts per stack is done through the sensor and encoder system that counts the quantity of parts so that they are pushed to the next conveyor when the maximum quantity of parts supported by the table is reached and then moved to the next process.

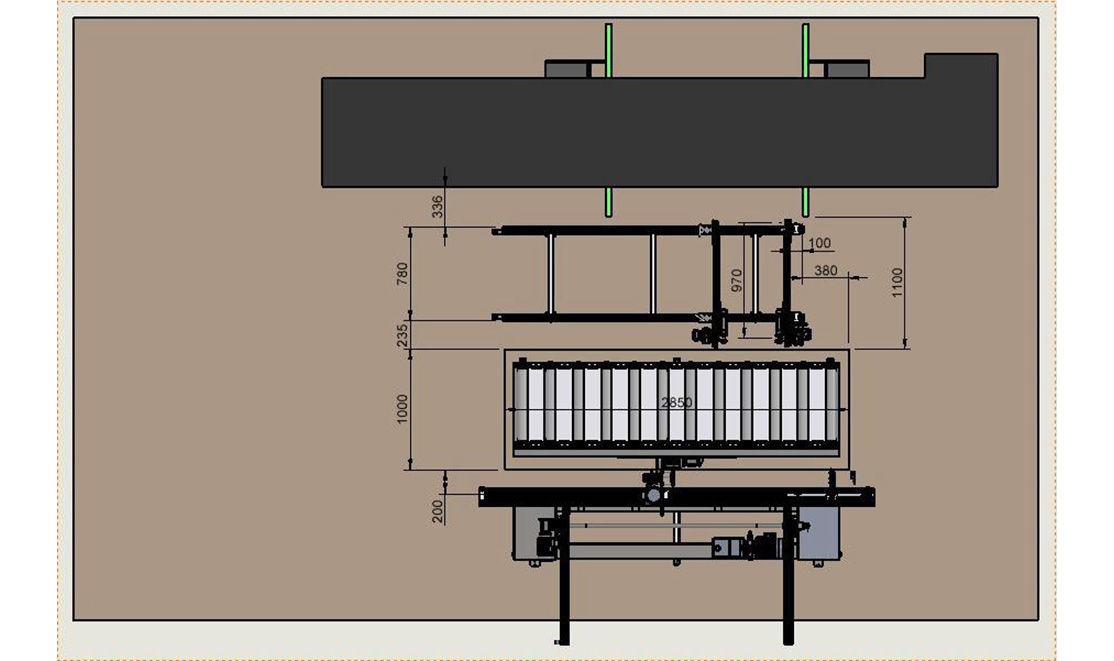

Lift table’s installation pit layout

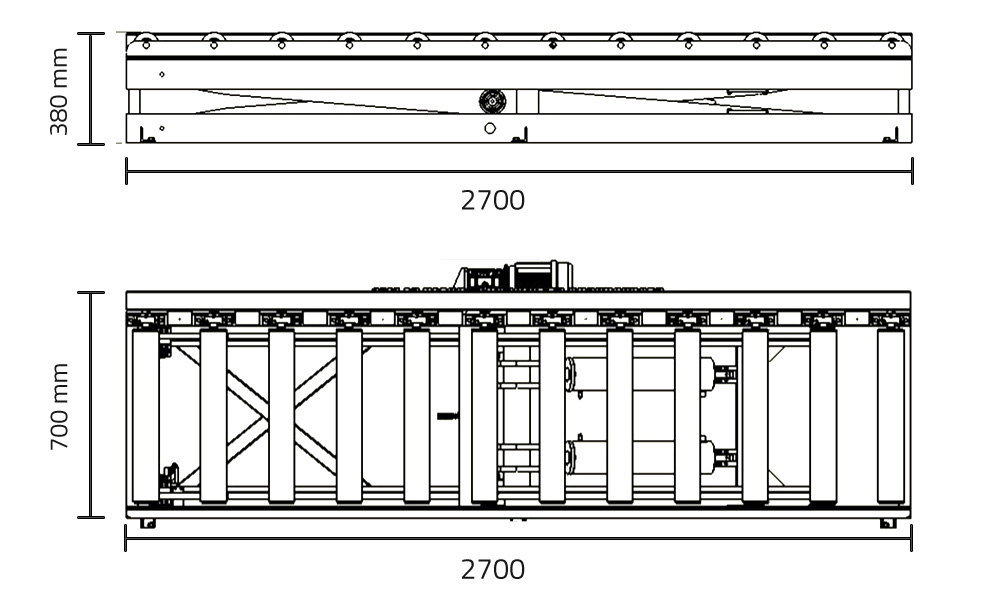

Equipment dimensions

| Dimensions | Measurement unit | |

|---|---|---|

| Total length (A) | mm | 2700 |

| Total width (B) | mm | 700 |

| Total height (C) | mm | 380 |

| Net weight | kg | 1070 |

Packaging and delivery

Complete Automatic unloader for drilling machines for export

| Automatic unloader for multiple machines | |

|---|---|

| Shipping guidance | Packages cannot be toppled over |

| Packaging specifications | Packages wrapped in stretch film |

| Total cubic measure | Package 1: Length 2550mm X Width 1050mm X Height 1050mm = 2.811m³ Package 2: Length 3350mm X Width 1500mm X Height 1600mm = 8.04m³ |

| Total net weight | 1070kg |

| Total gross weight | 1100kg |

| Total number of boxes | 02 Boxes |

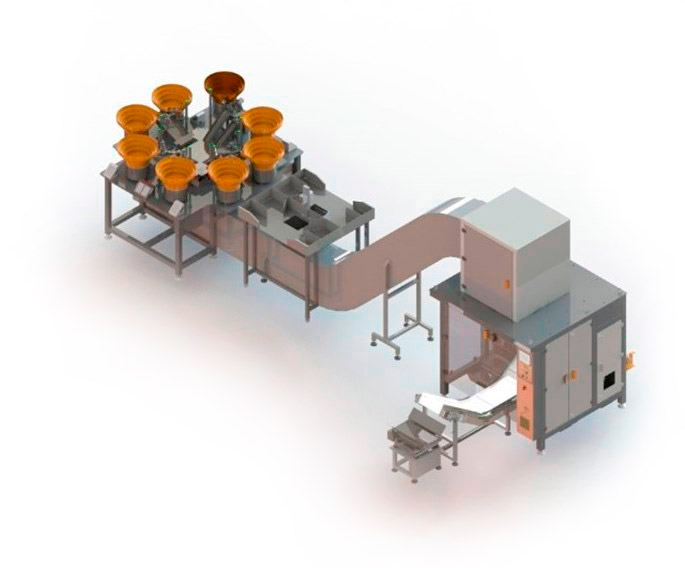

Other machines

CE-01 counting and packaging machine

CE-02 counting and packaging machine

CE-01 Mini counting and packaging machine

Heat-shrinkable film packaging machine

Automatic orbital Stretch film wrapping machine

Semiautomatic orbital Stretch film wrapping machine ESJ 900

Semiautomatic orbital Stretch film wrapping machine ESJ 1200

Semiautomatic orbital Stretch film wrapping machine ESJ 1600

Semiautomatic orbital Stretch film wrapping machine ESJ 2000

Edge polisher Naked

Cirux bridge Saw

Oblicus 45º Cutting Saw

F400-CS Drilling Machine

F400-T Drilling Machine

F601 drilling machine

05 Axis Machining Center