Why do I need this machine?

Why do I need this machine?

High rate of technical support due to missing parts/hardware;

Recurring complaints in the after-sales;

I want to automate my packaging process;

Low productivity due to manual processes;

High costs of raw materials in the packaging of my product;

Waste of materials when sending extra parts, due to low precision in separation;

Disruption in the production chain caused by delays in the delivery of outsourced kits.

If you have any of these problems, talk to us!

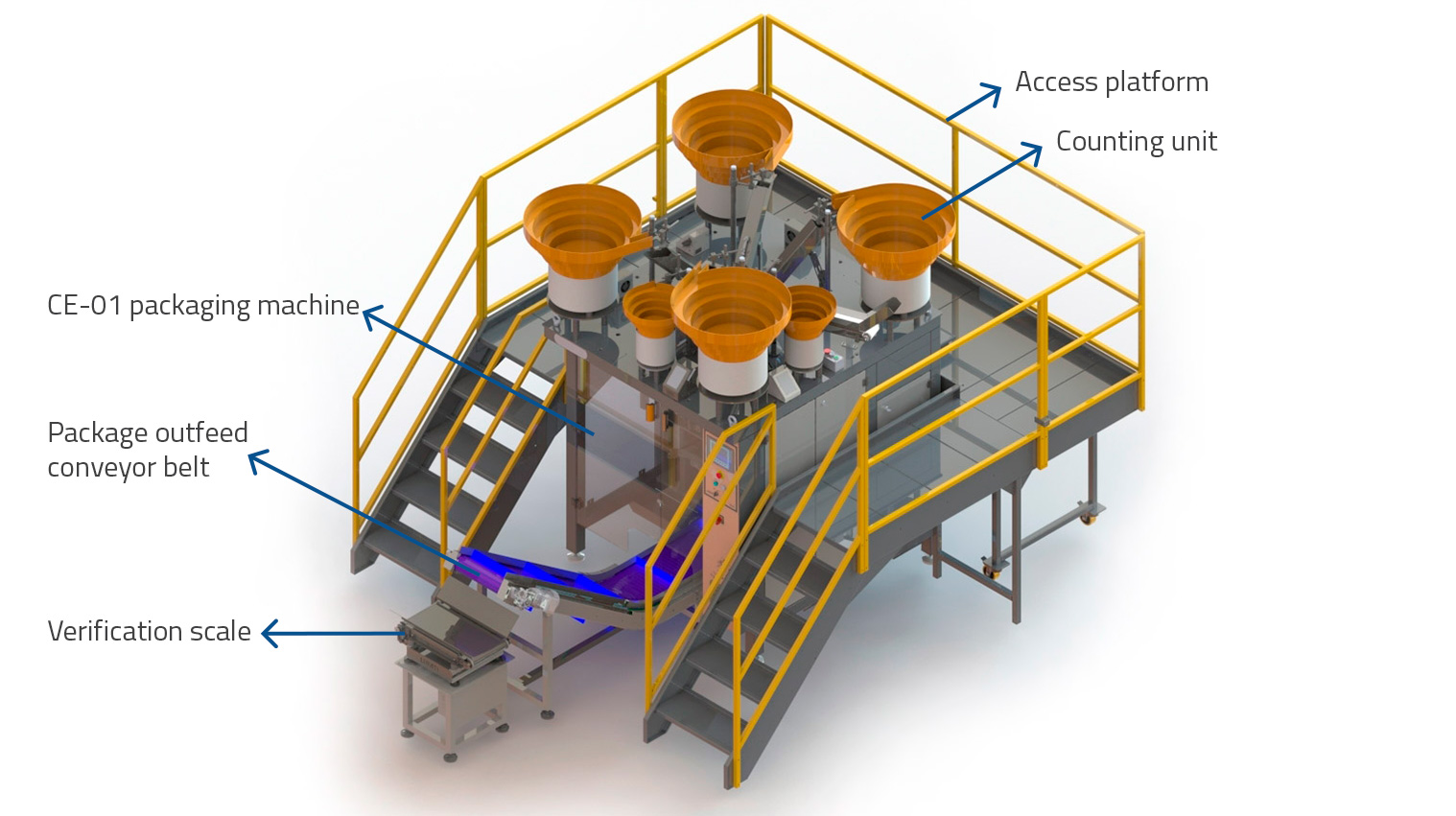

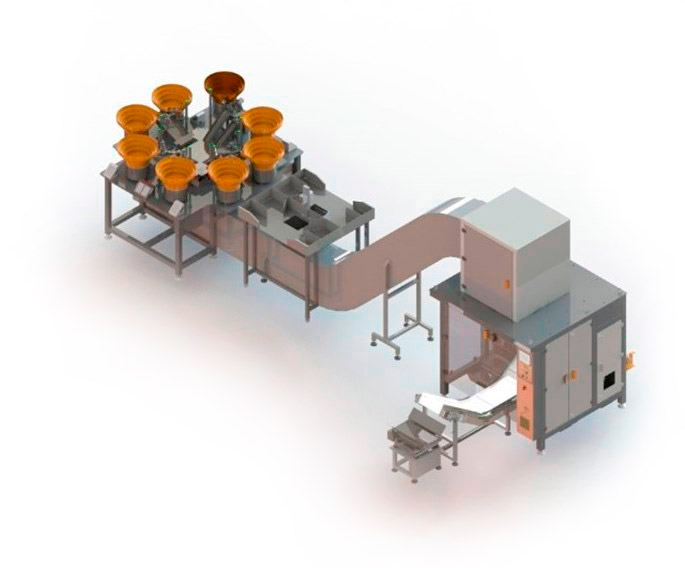

CE-01 counting and packaging machine

Prices starting atUSD 79.900,00*

* Check shipping conditions

Product manufactured in accordance with safety standards

100% Brazilian manufacturing

1-year warranty

Uses compressed air

Touch Screen Panel

High-precision scale

Customizable layout

Less human interference

Why choose the CE-01 counting and packaging machine?

Less human interference in the process.

Cost reduction in the purchase of inputs;

Production with agility and precision;

Intuitive Touch Screen Panel;

High-precision verification scale;

Low energy and pneumatic consumption;

Optimized layout, using little factory area.

Product manufactured in accordance with safety standards

100% Brazilian manufacturing

1-year warranty

Uses compressed air

Touch Screen Panel

High-precision scale

Customizable layout

Less human interference

The CE-01 counting and packaging machine is ideal for those seeking to automate their packaging processes with accurate and high-performance results. Furthermore, it offers the option of separating hardware into sub-kits within the same package.

The equipment is customizable, adapting to different segments:

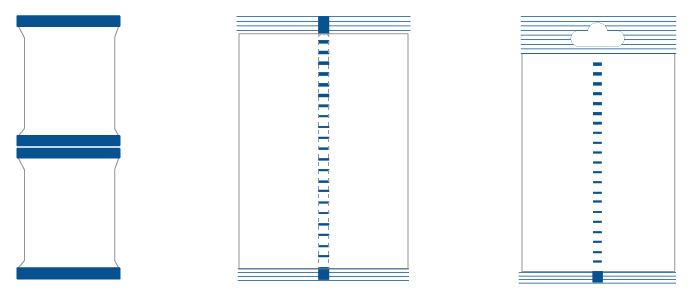

Packs the parts in a single kit or divided into several sub-kits

Auto Parts

Toys

Electric

Electronic

Hydrosanitary

Plastic injection

Metallurgical

Furniture

Textile

Other segments

Technological highlights

The CE-01 counting and packaging machine automatically counts and packs small pieces into plastic packages.

The feeders count and separate of the pieces. So the machine produces the plastic package from a plain transparent or printed film. This process occurs sequentially following the command previously programmed on the equipment's HMI.

The machine can operate with up to 10 feeders and each combination of elements can be packed individually or combined according to needs. Packages can be identified by a printer connected to the machine.

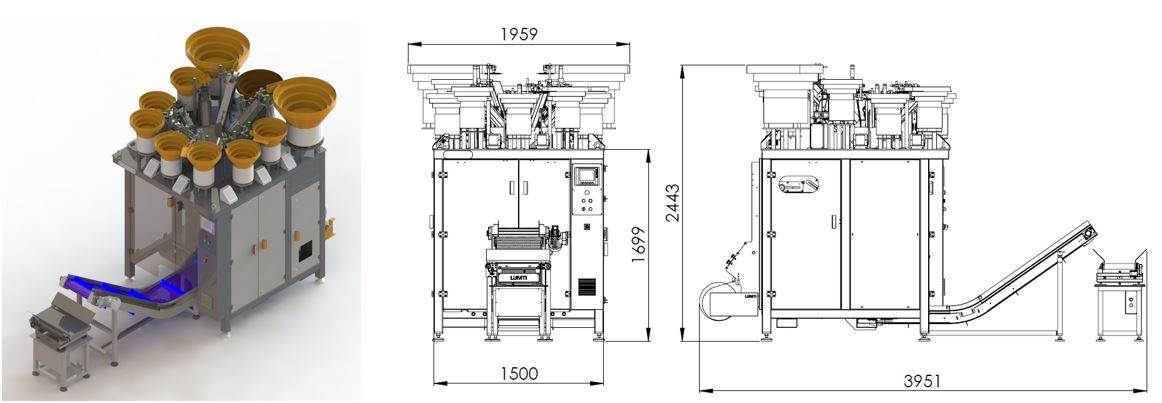

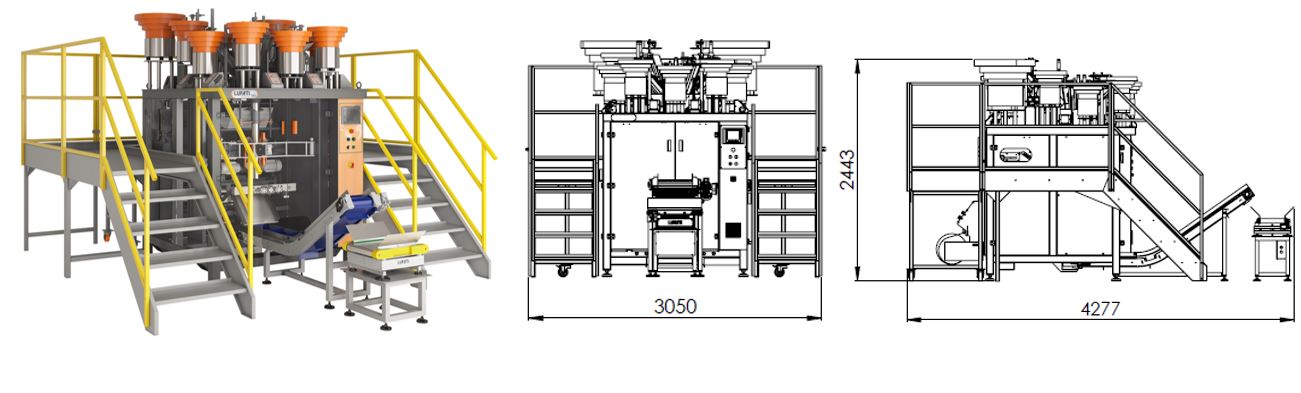

Equipment dimensions

This machine offers, as an option, a lateral access platform, which allows the supply of parts to the feeders. In this way, the layout will be defined only by the machine or by the machine + optional (platform), according to the following diagrams:

Layout without side-access platform

Layout with side-access platform

| Dimensions (layout) | Length | Width | Height |

|---|---|---|---|

| Without platform | 3951mm | 1959mm | 2443mm |

| With platform | 4277mm | 3050mm | 2443mm |

Packaging and delivery

Complete ce-01 for export

*Photos of the machine packed without platform

| CE-01 machine without platform | |

|---|---|

| Shipping guidance | The machine cannot be toppled over |

| Packaging specifications | Tubular structure welded with insulation |

| Total cubic measure | 12,3m³ |

| Total net weight | 1900kg |

| Total gross weight | 2400kg |

| Total number of boxes | 01 box : W x H x D (2150x2480x2300mm) |

| CE-01 machine with platform | |

|---|---|

| Shipping guidance | The machine cannot be toppled over |

| Packaging specifications | Tubular structure welded with insulation |

| Total cubic measure | 24,6m³ |

| Total net weight | 2200kg |

| Total gross weight | 2700kg |

| Total number of boxes | 02 boxes: W x H x D (2150x2480x2300mm) |

Other machines

CE-01 counting and packaging machine

CE-02 counting and packaging machine

CE-01 Mini counting and packaging machine

Heat-shrinkable film packaging machine

Automatic orbital Stretch film wrapping machine

Semiautomatic orbital Stretch film wrapping machine ESJ 900

Semiautomatic orbital Stretch film wrapping machine ESJ 1200

Semiautomatic orbital Stretch film wrapping machine ESJ 1600

Semiautomatic orbital Stretch film wrapping machine ESJ 2000

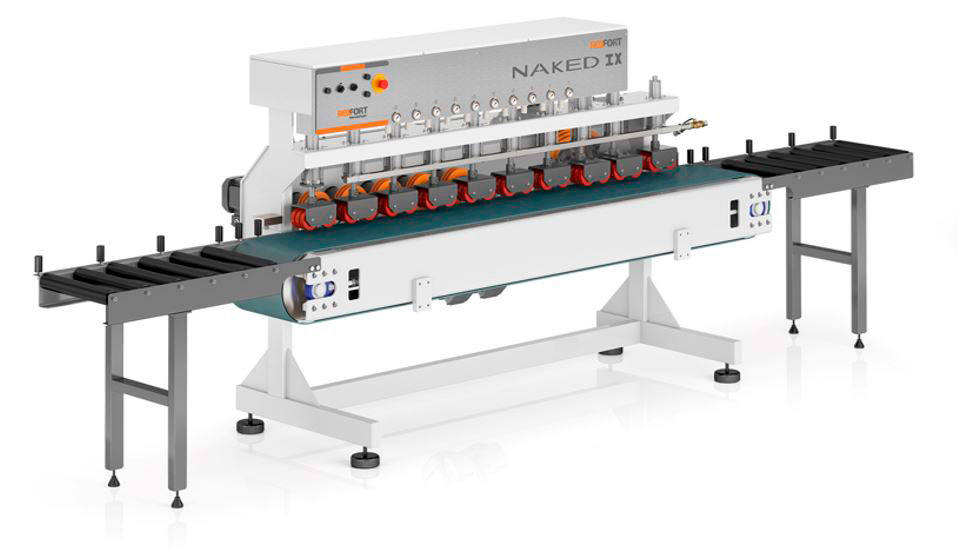

Edge polisher Naked

Cirux bridge Saw

Oblicus 45º Cutting Saw

F400-CS Drilling Machine

F400-T Drilling Machine

F601 drilling machine

05 Axis Machining Center