Why do I need this machine?

Why do I need this machine?

Recurring complaints in the after-sales;

High rate of technical support due to missing parts/hardware;

I want to automate my packaging process;

Low productivity due to manual processes;

Disruption in the production chain caused by delays in the delivery of outsourced kits;

High costs of raw materials in the packaging of my product;

Need to pack pre kits, forming a master package;

I need equipment to pack complex kits or larger pieces into my product MIX.

If you have any of these problems, talk to us!

CE-02 counting and packaging machine

Prices starting atUSD 94.900,00*

* Check shipping conditions

Product manufactured in accordance with safety standards

100% Brazilian manufacturing

1-year warranty

Touch Screen Panel

High-precision scale

Customizable layout

Assembly instructions feeders;

Operates with up to 60 feeders

Makes the product MIX more flexible;

Why choose the CE-02 counting and packaging machine?

Less human interference in the process.

Cost reduction in the purchase of inputs;

Production with agility and precision;

Intuitive Touch Screen Panel;

High-precision verification scale;

Customized layout according to needs;

Manual feeding table;

Operates with up to 60 feeders;

Makes the product MIX more flexible;

Assembly instructions feeders;

Low energy and pneumatic consumption.

Product manufactured in accordance with safety standards

100% Brazilian manufacturing

1-year warranty

Touch Screen Panel

High-precision scale

Customizable layout

Assembly instructions feeders;

Operates with up to 60 feeders

Makes the product MIX more flexible;

The CE-02 counting and packaging machine allows the packaging of complex kits as well as the packaging of multiple kits to form a master package. Ideal for those who want to make the product mix more flexible and minimize errors in the packaging process.

The equipment is customizable, adapting to different segments:

Auto Parts

Toys

Electric

Electronic

Hydrosanitary

Plastic injection

Metallurgical

Furniture

Textile

Other segments

Technological highlights

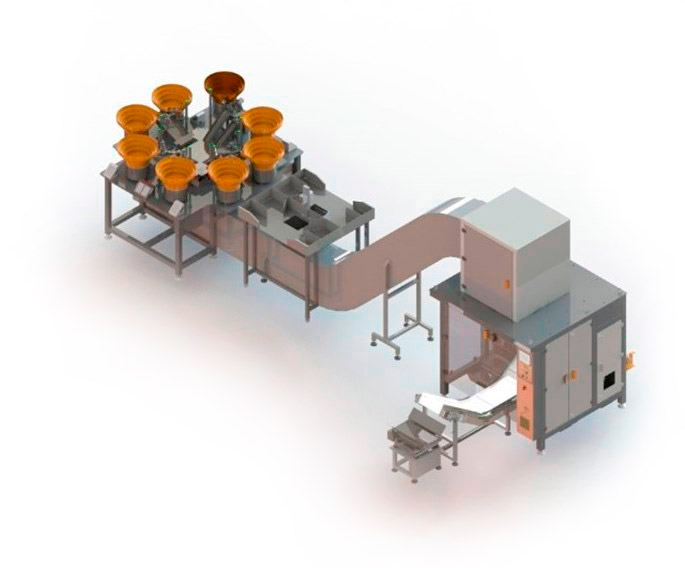

The CE-02 counting and packaging machine automatically counts and packs pieces into plastic packages.

The feeders count and separate of the pieces. So the machine produces the plastic package from a plain transparent or printed film. This process occurs sequentially following the command previously programmed on the equipment's HMI.

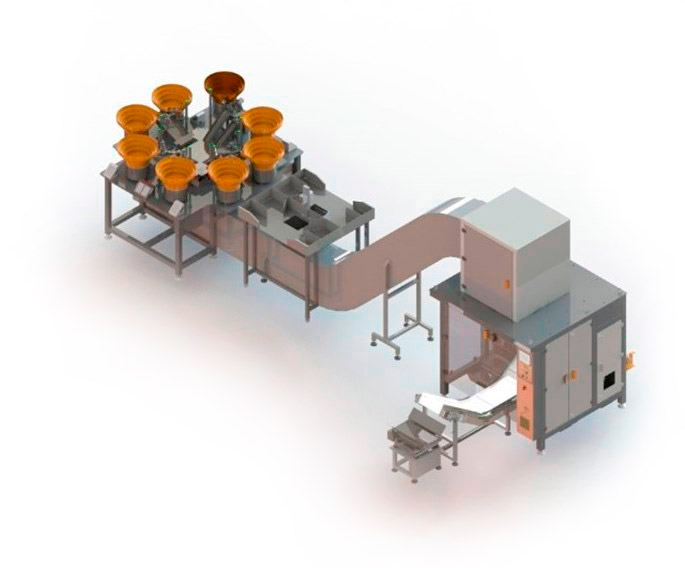

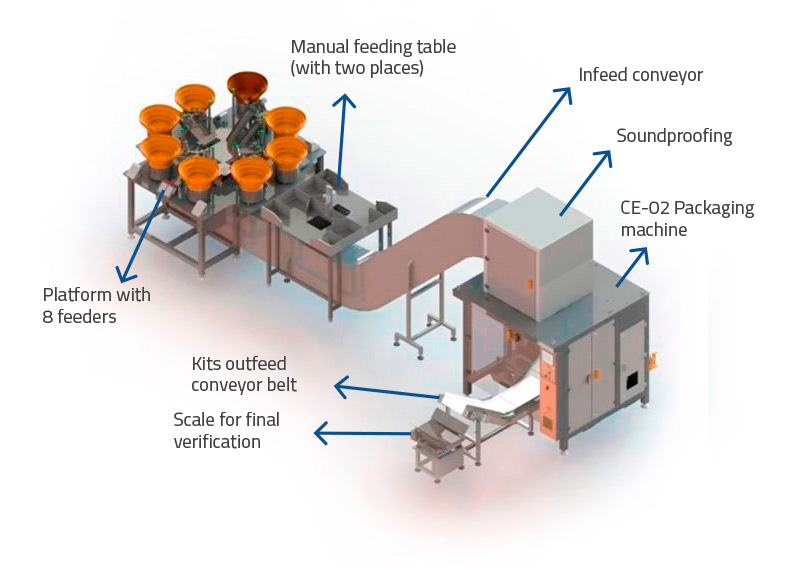

The machine can operate with up to 60 feeders, separated into modules, which can be open or have soundproofing (optional item), as shown in the picture below:

*Module with soundproofing

*optional

*Module without soundproofing

As it has a large number of feeders, the equipment provides flexibility in the products mix, being able to pack each combination of elements individually or combined with pre-packaged items.

Packages can be identified by a printer connected to the machine.

Optional

In addition to the printer for kit identification and soundproofing, the machine offersother options, as seen below:

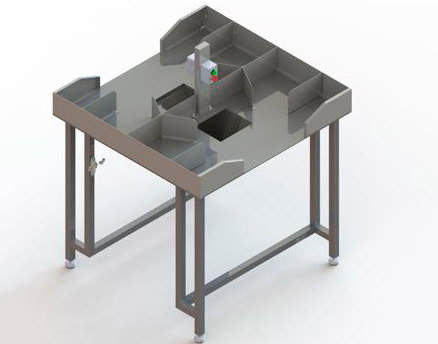

Assembly instructions feeding table

With this module connected to the machine, printed materials are included in the package. This module is generally used to pack the product’s assembly manuals.

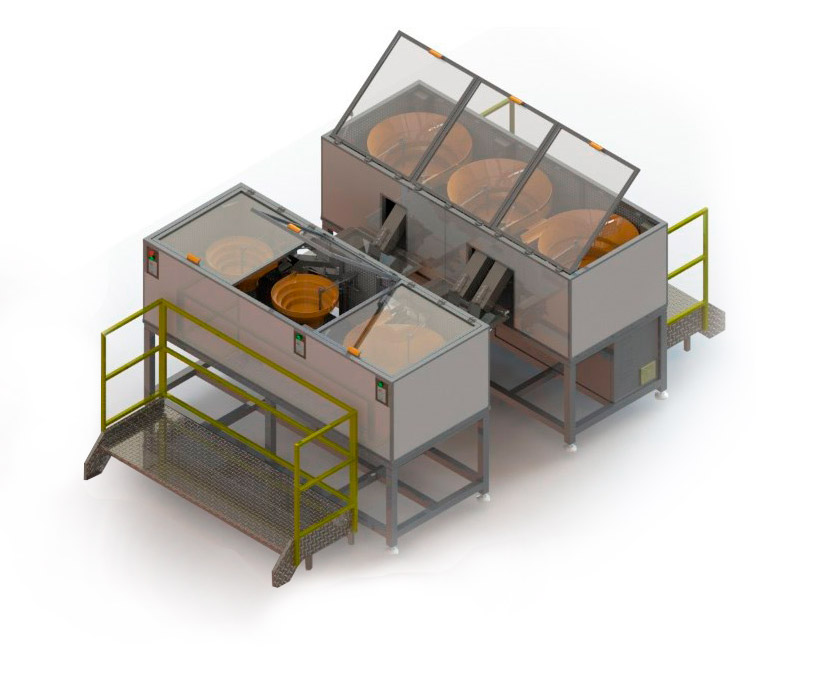

Manual feeding table

Allows the inclusion of the parts manually and operates with 01 or 02 operators simultaneously (according to the need). This module is generally utilized when there is a need to include bigger pieces, not packed by conventional feeders.

PIC-TO-LIGHT module

PIC-TO-LIGHT module

This module is an option to replace or complement the machine's standard feeding set (picture below):

In the PIC-TO-LIGHT module, each of the 6 openings works as a feeder.

Each opening contains 1 internal sensor with a digital indicator, which shows the operator how many parts they must remove from the opening to insert in the package. However, the operator only removes the parts when the green light is on next to the digital quantity indicator, ensuring the accuracy of the parts separation.

When all parts have been removed from each programmed opening, the operator will give the machine the command to carry out the packaging.

The module is generally utilized when there is great diversity of parts in the kit and limitation in the physical space of the factory (a pic-to-light module is more compact than a conventional one).

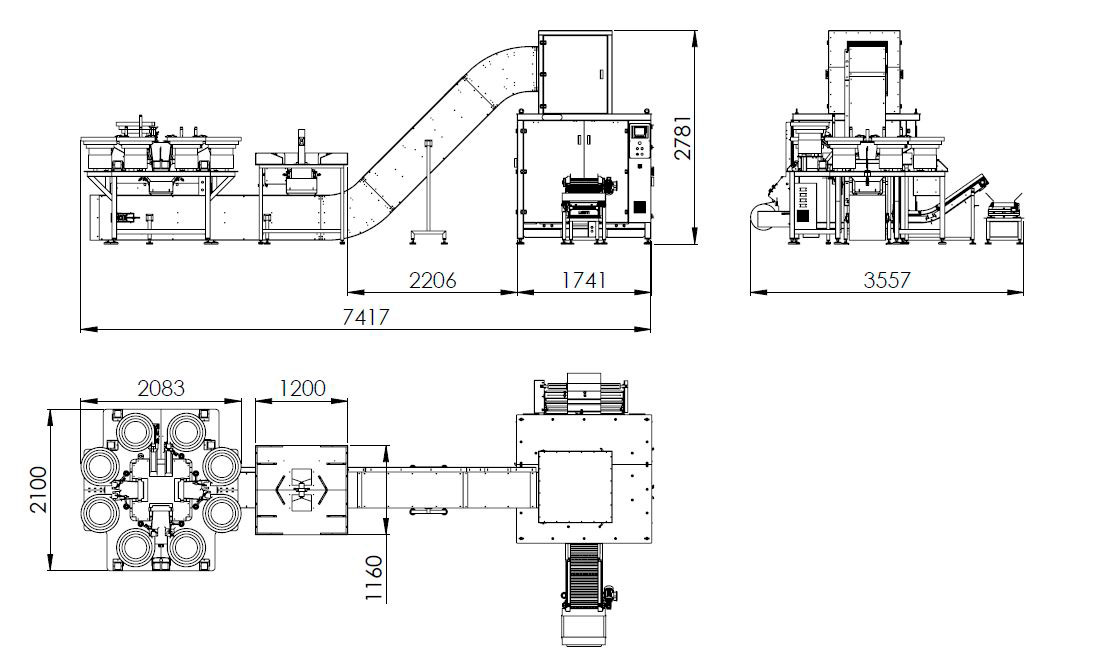

Equipment dimensions

This machine can operate with up to 60 feeders and it is totally customizable. In this way, the layout will be defined by the quantity of Packing Modules added, that is, by the quantity of feeders.

The diagram below demonstrates the Layout with only 1 module - 8 feeders:

Other machines

CE-01 counting and packaging machine

CE-02 counting and packaging machine

CE-01 Mini counting and packaging machine

Heat-shrinkable film packaging machine

Automatic orbital Stretch film wrapping machine

Semiautomatic orbital Stretch film wrapping machine ESJ 900

Semiautomatic orbital Stretch film wrapping machine ESJ 1200

Semiautomatic orbital Stretch film wrapping machine ESJ 1600

Semiautomatic orbital Stretch film wrapping machine ESJ 2000

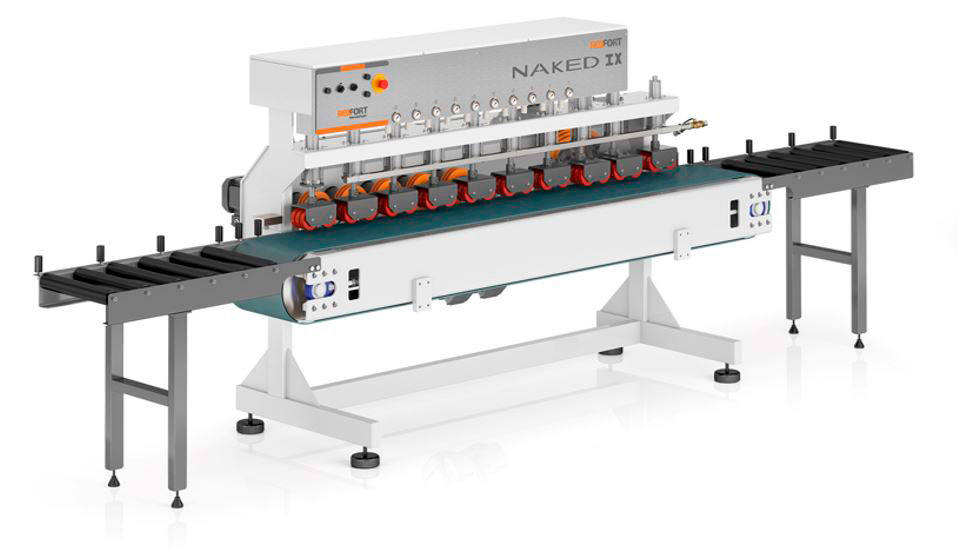

Edge polisher Naked

Cirux bridge Saw

Oblicus 45º Cutting Saw

F400-CS Drilling Machine

F400-T Drilling Machine

F601 drilling machine

05 Axis Machining Center