Why do I need this machine?

Why do I need this machine?

Low productivity due to manual processes;

Difficulty in standardizing the finishing of the pieces;

Difficulty in executing out-of-square or curved cuts;

High labor costs;

Inability to effectively control productivity;

Need to reduce delivery time.

If you have any of these problems, talk to us!

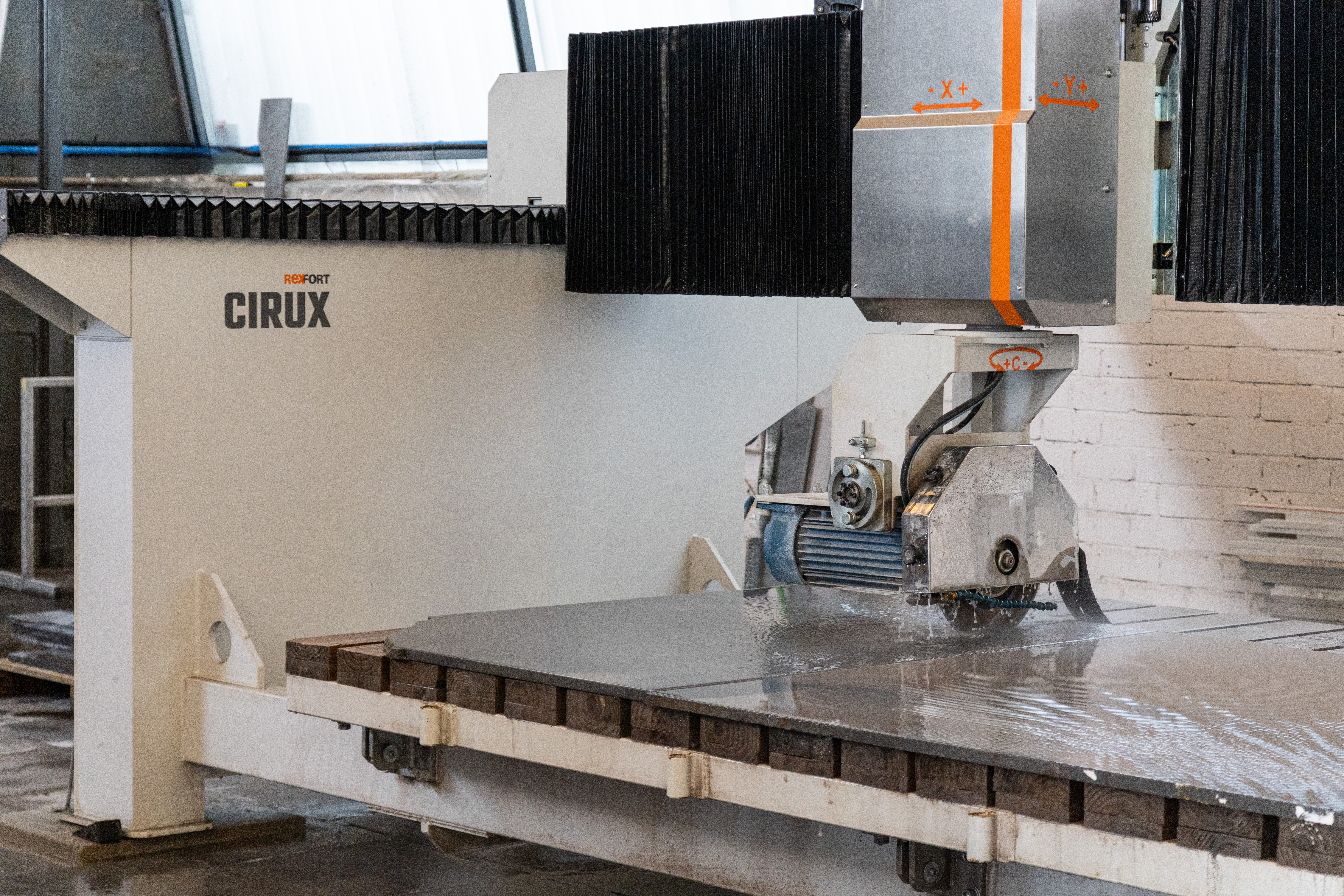

Cirux bridge Saw

Prices starting atUSD 69.900,00*

* Check shipping conditions

100% Brazilian manufacturing

1-year warranty

Uses compressed air

Higher productivity

Less human interference

Standardization of results

Use recycled water

Why choose the Cirux Bridge Saw?

Standard, high-level finishing without rework;

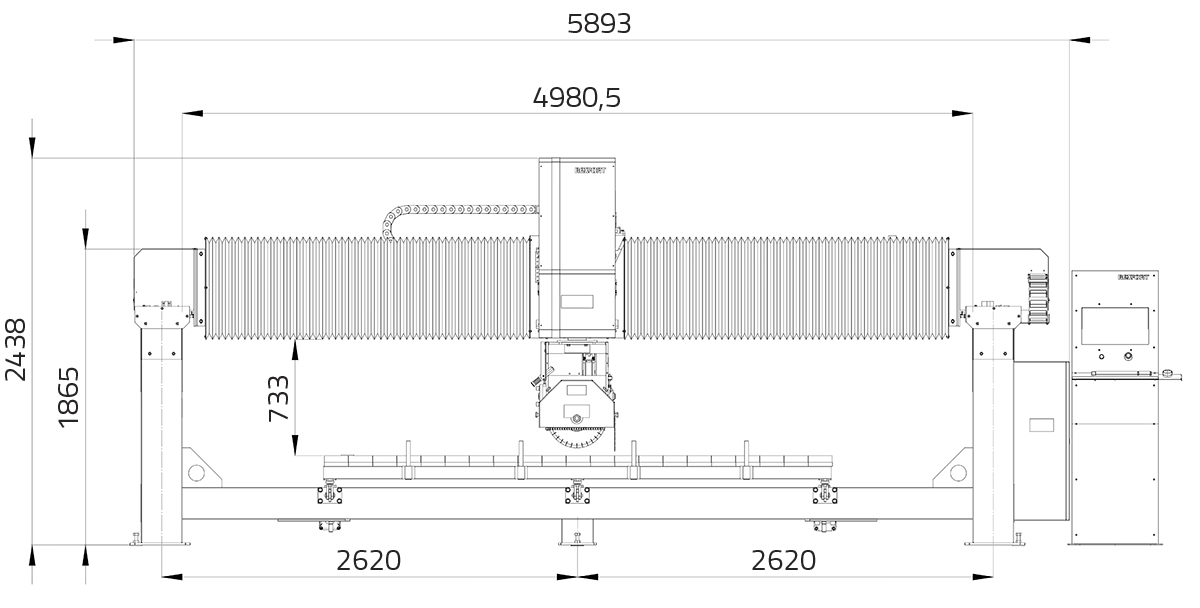

Monoblock structure with vibration absorption system;

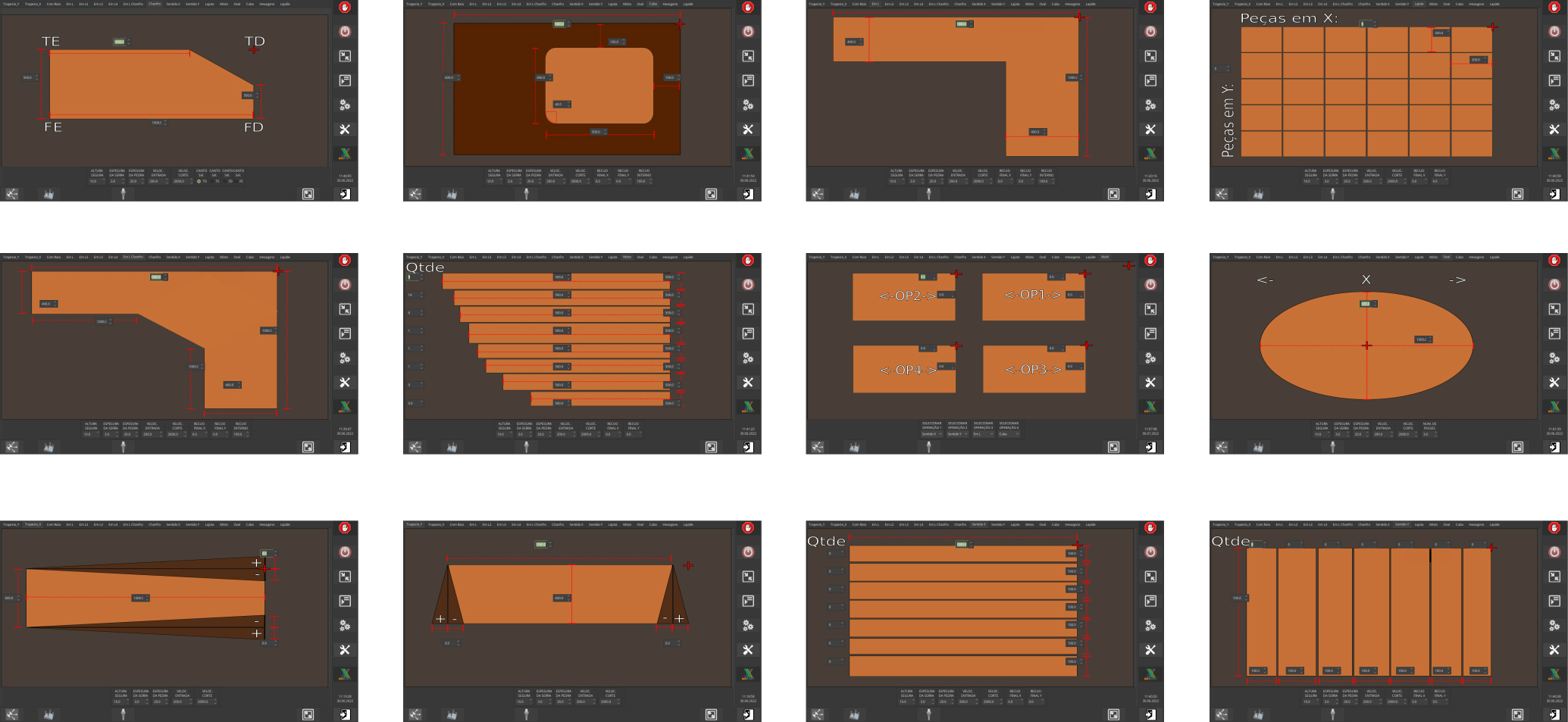

Cutting programming software with 12 configured plans;

Tilting system with pneumatic activation for table;

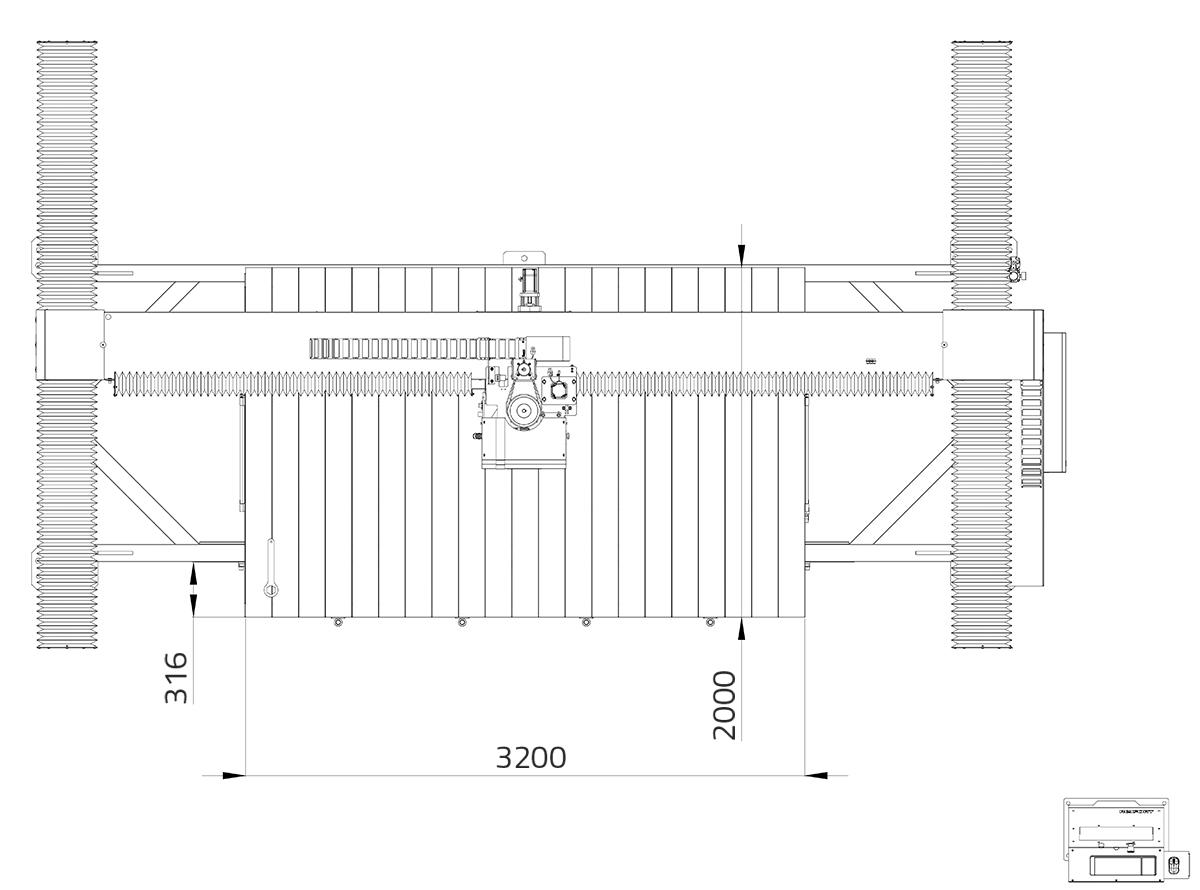

Works with pieces up to 3200mm wide;

4-axis CNC control (X, Y, Z and B);

Straight and interpolated cuts in 03 axes: X, Y and B;

Assembly with low floor fixing demand;

Reduction in material handling time;

100% Brazilian manufacturing

1-year warranty

Uses compressed air

Higher productivity

Less human interference

Standardization of results

Use recycled water

The CIRUX bridge saw is ideal for those who want to increase productivity and quality of their results. With exclusive cutting programming software, it allows easy use of the equipment through pre-defined macros, or using a dxf drawing as a basis for differentiated cuts.

Technological highlights

The sheets are manually positioned on the cutting table, which has a wooden covering. After positioning the sheet, the operator must select the cutting program using exclusive intuitive software.

The CIRUX bridge saw has a self-supporting monoblock structure with a vibration absorption system on the walls and on the cutting bridge, ideal for making precise cuts, which can be straight or interpolated, across the X, Y and Z axes.

During the entire cutting process, water is released to clean the sludge generated and cool the stone, and, to prevent oxidation of the linear guides X and Y, the machine has centralized manual lubrication and a protective bellows cover system in these parts.

Ideal for the following works:

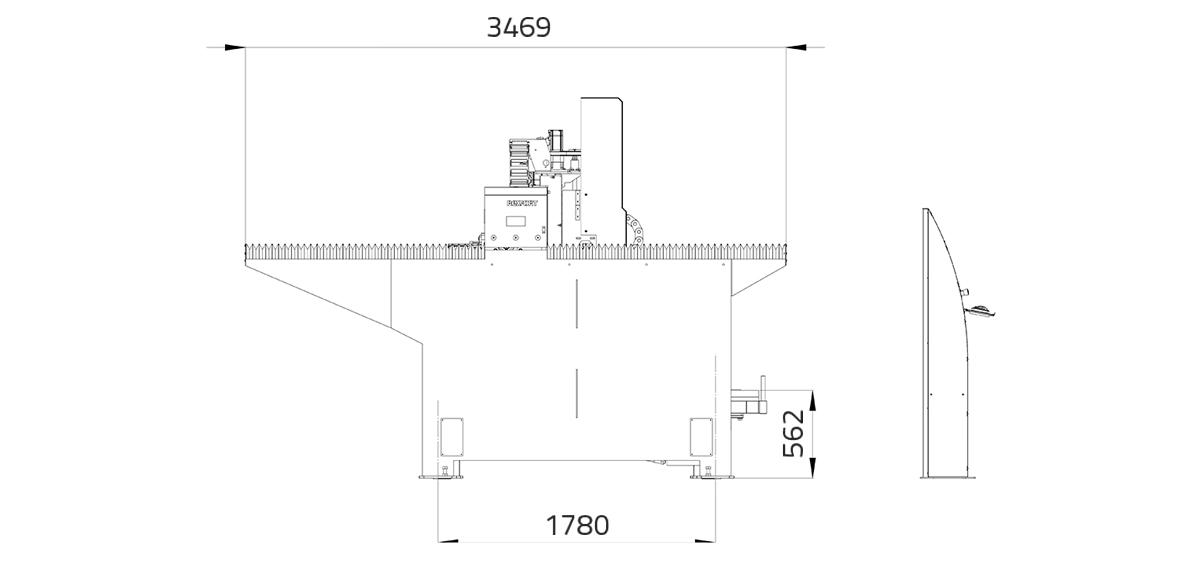

Equipment dimensions

| Length | Width | Height |

|---|---|---|

| 3469 | 5893 | 2438 |

**Dimensions in millimeters

Packaging and delivery

Complete Cirux Bridge Saw for export

| Cirux bridge Saw | |

|---|---|

| Shipping guidance | Packages cannot be toppled over |

| Packaging specifications | 1 Package wrapped in stretch film |

| Total cubic measure | (Length x Width x Height) 2410 x 6000 x 2445 mm = 36,4 m³ |

| Total net weight | 4200kg |

| Total gross weight | 4300kg |

| Total number of boxes | 01 Box |

Other machines

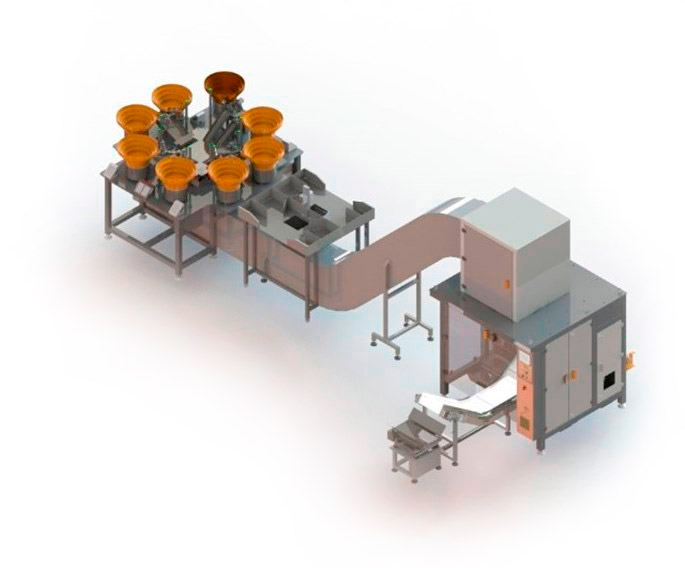

CE-01 counting and packaging machine

CE-02 counting and packaging machine

CE-01 Mini counting and packaging machine

Heat-shrinkable film packaging machine

Automatic orbital Stretch film wrapping machine

Semiautomatic orbital Stretch film wrapping machine ESJ 900

Semiautomatic orbital Stretch film wrapping machine ESJ 1200

Semiautomatic orbital Stretch film wrapping machine ESJ 1600

Semiautomatic orbital Stretch film wrapping machine ESJ 2000

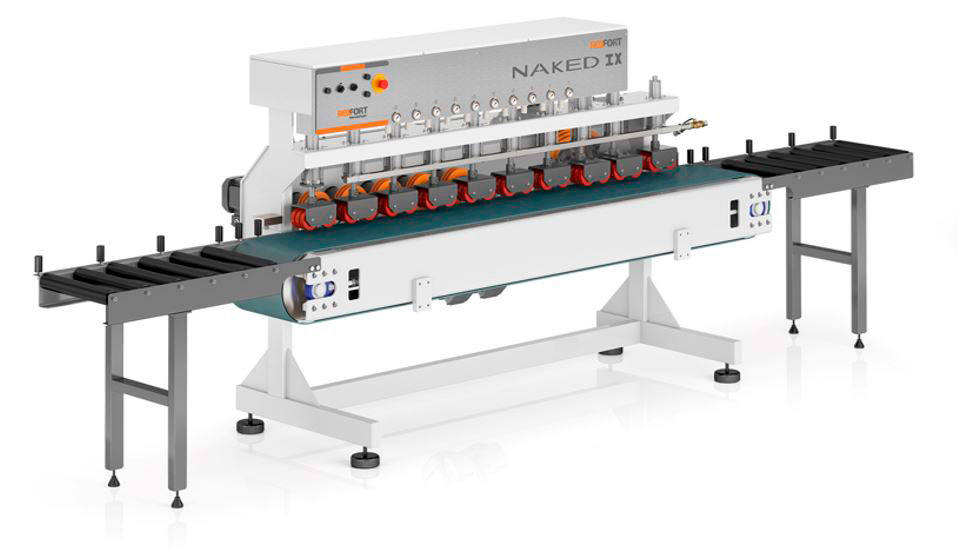

Edge polisher Naked

Cirux bridge Saw

Oblicus 45º Cutting Saw

F400-CS Drilling Machine

F400-T Drilling Machine

F601 drilling machine

05 Axis Machining Center