Why do I need this machine?

Why do I need this machine?

Low productivity due to manual processes;

Difficulty in standardizing the finishing of the pieces;

High costs with raw material and labor;

Inability to effectively control productivity;

Need to reduce delivery time.

If you have any of these problems, talk to us!

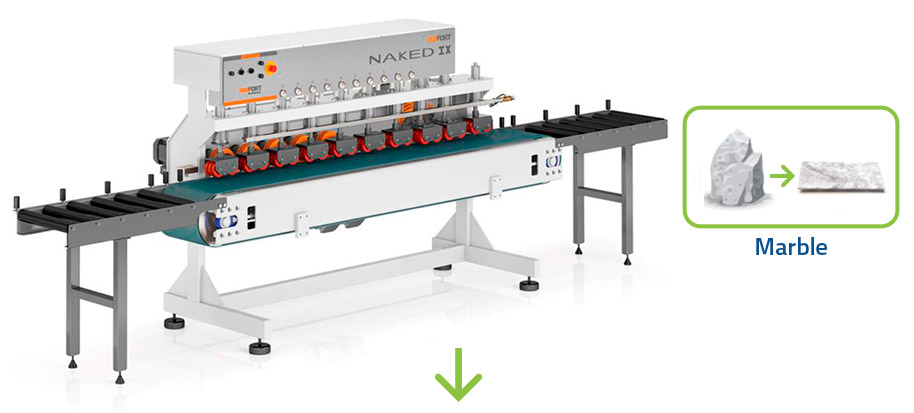

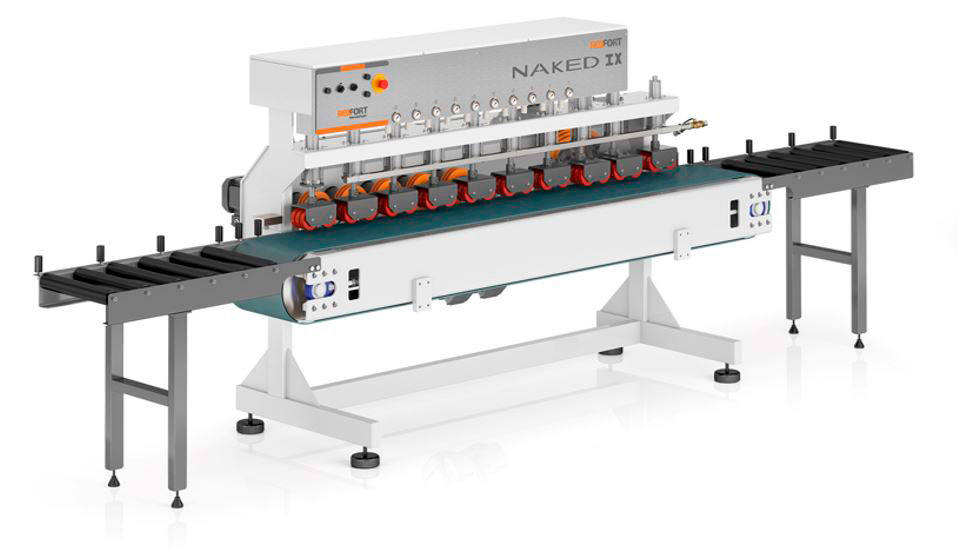

Edge polisher Naked

Prices starting atUSD 34.690,00*

* Check shipping conditions

100% Brazilian manufacturing

1-year warranty

Uses compressed air

Higher productivity

Less human interference

High gloss finish

Standardization of results

Use recycled water

Why choose the Naked Edge Polisher?

Production up to 12 times greater than the manual process;

Standard, high-gloss finish without rework or wax;

Reduction of costs with raw material and workforce;

Optional: 4'' HMI and supporting arm.

100% Brazilian manufacturing

1-year warranty

Uses compressed air

Higher productivity

Less human interference

High gloss finish

Standardization of results

Use recycled water

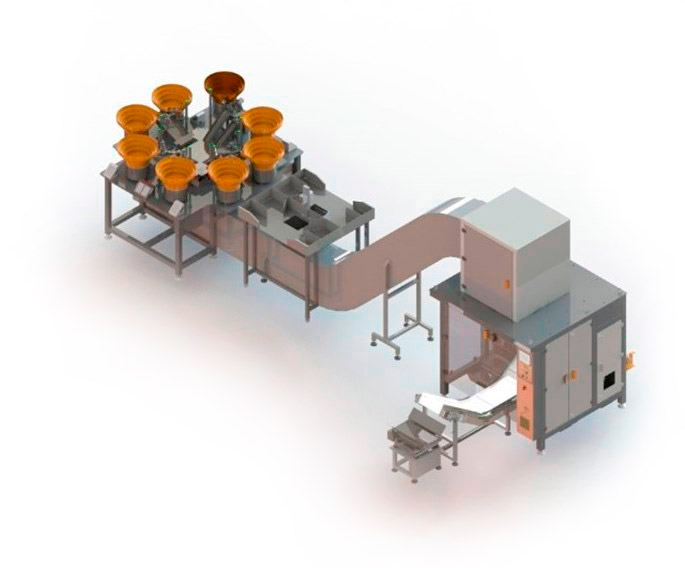

The NAKED edge polisher model is the ideal machine for those who want to standardize the quality of the finish with high gloss results, reducing workforce, rework and delivery time in this process.

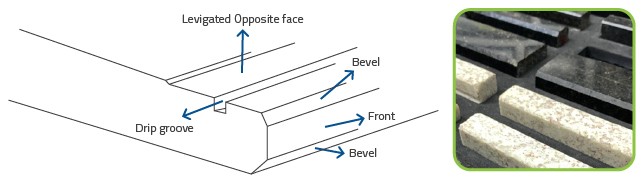

Perfect for the finishes:

Technological highlights

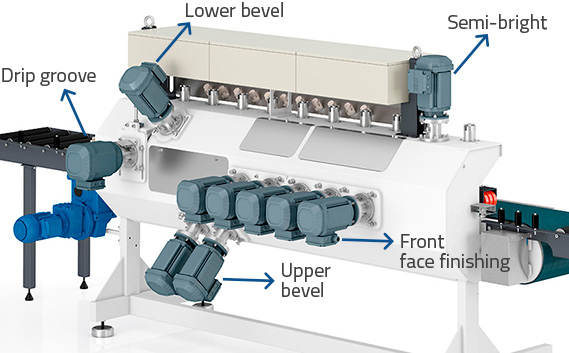

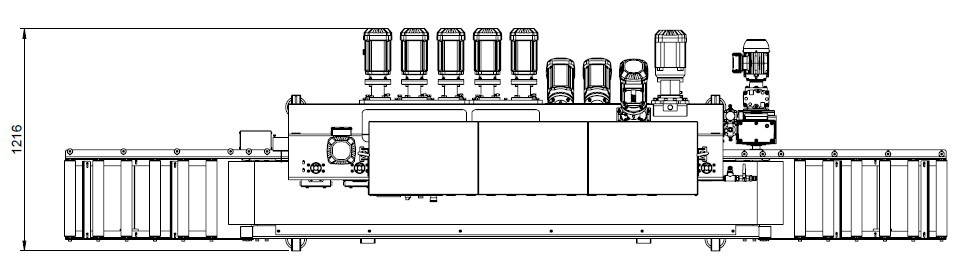

Parts are manually fed onto the infeed table. They are moved through a motorized conveyor belt, passing through the heads that will polish the edges. The pressing clamps keep the pieces firmly on the belt for the perfect polishing of the edges.

The machine operates with 10 heads, distributed according to the diagram below, to provide a better finishing of the part:

- 05 Heads for front face finishing

- 02 Upper bevel heads fixed at 45°

- 01 Lower bevel head fixed at 45°

- 01 Head for semi-bright on the opposite face

- 01 Head for drip groove

During the entire polishing process, water is released to cool the abrasives and clean the sludge generated by the wear of the part.For this process, the equipment allows the use of recycled water, if the customer has a settling tank in its facilities.

Get to know the 3 cornerstones of the rexfort edge polisher

1) Structure

The structure of the NAKED edge polisher is manufactured in a MONOBLOCK concept, that is, the chassis of the machine is made up of only one part, unlike conventional models which are made up of several welded parts.

This concept makes the machine more robust and provides greater durability and strength to the structure, reducing the risk of damage resulting from use.

It's the perfect structure to absorb the head’s vibration and deliver impeccable results.

- Robust structure

- Greater durability

- Lower structure vibration

- Impeccable finishes

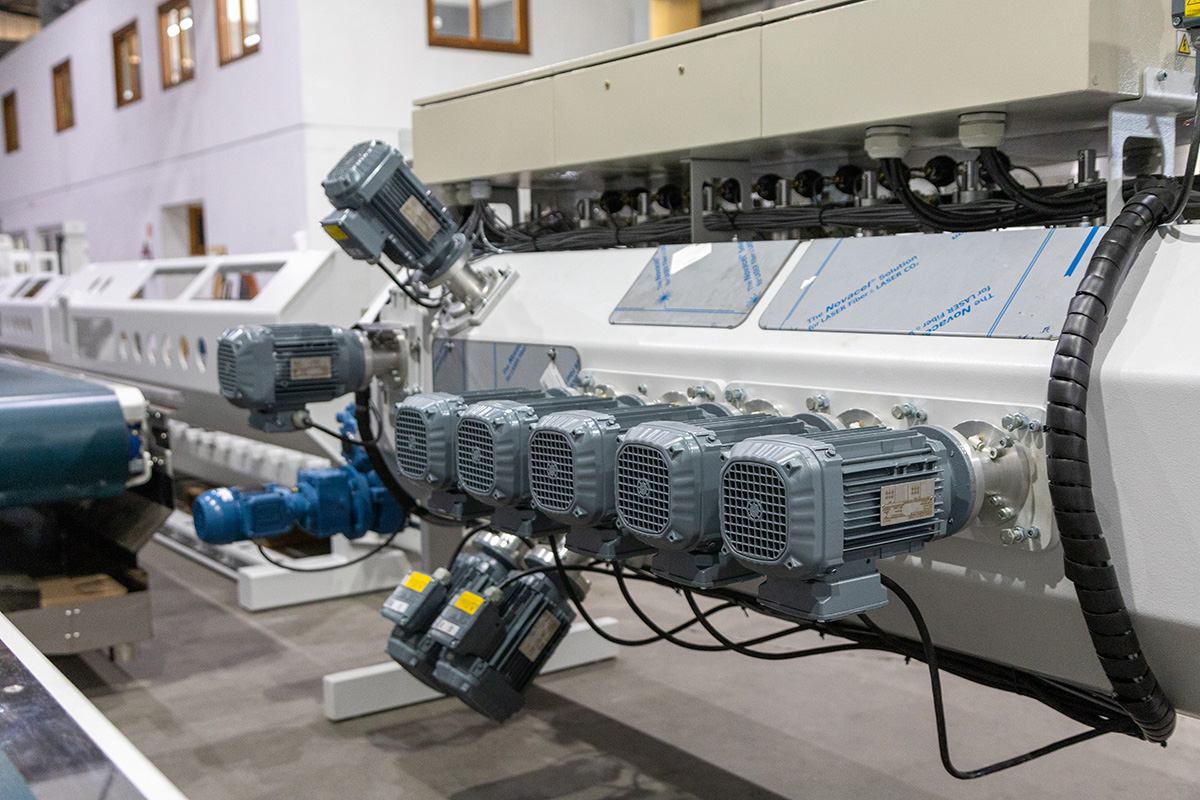

2) Heads

The Naked edge polisher is made up of heads with fixed motors. The movement is performed only by the head, which is made of aluminum in order to help distribute the vibration caused by the movement of the abrasive with the stone.

With two fixed motors, the machine has a plate located between the motor and the structure, with the function of aligning and allowing regulation of the heads

Important tip: When the motor is not fixed, that is, when it moves along with the head, its weight creates some looseness in the structure, reducing the efficiency of the polishing process and increasing the technical support rate.

- Firm and looseness -free motors and heads

- Longer abrasive life

- Better absorption of vibration in the process

- Efficiency in the polishing process

- Reduction of the technical support rate

3) Pressing rollers

The Naked edge polisher pressing rollers have pneumatic systems, unlike conventional models that use spring systems.

Unlike the spring system, the pneumatic pressing roller allows automatic adjustment to the thickness of the stone, preventing the abrasive from expelling the piece during the polishing process.

Besides, it is possible to control the pressure applied to each pressing roller, ensuring a uniform finish and greater quality control.

- Perfect fit to stone thickness

- Uniform finish

- Quality Control

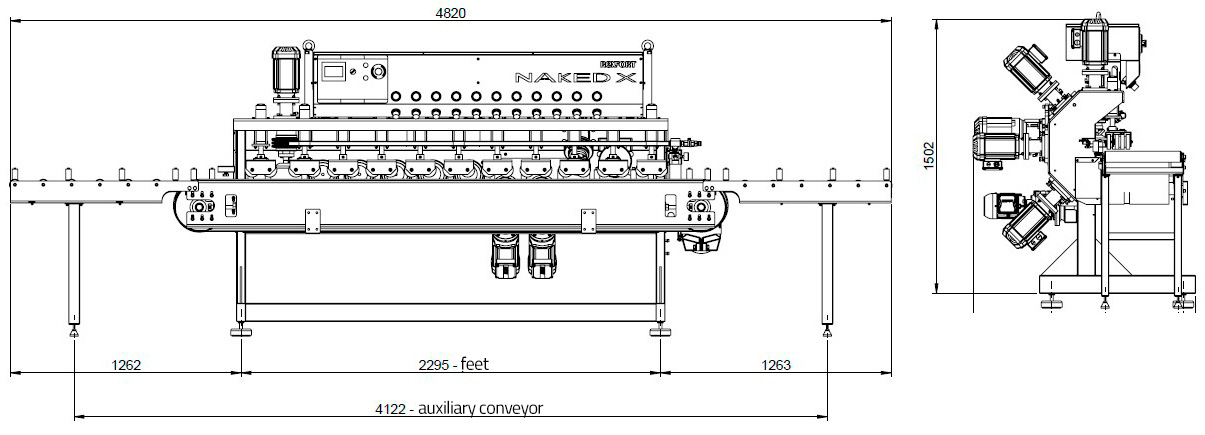

Equipment dimensions

| Length | Width | Height |

|---|---|---|

| 4820 | 1216 | 1502 |

**Dimensions in millimeters

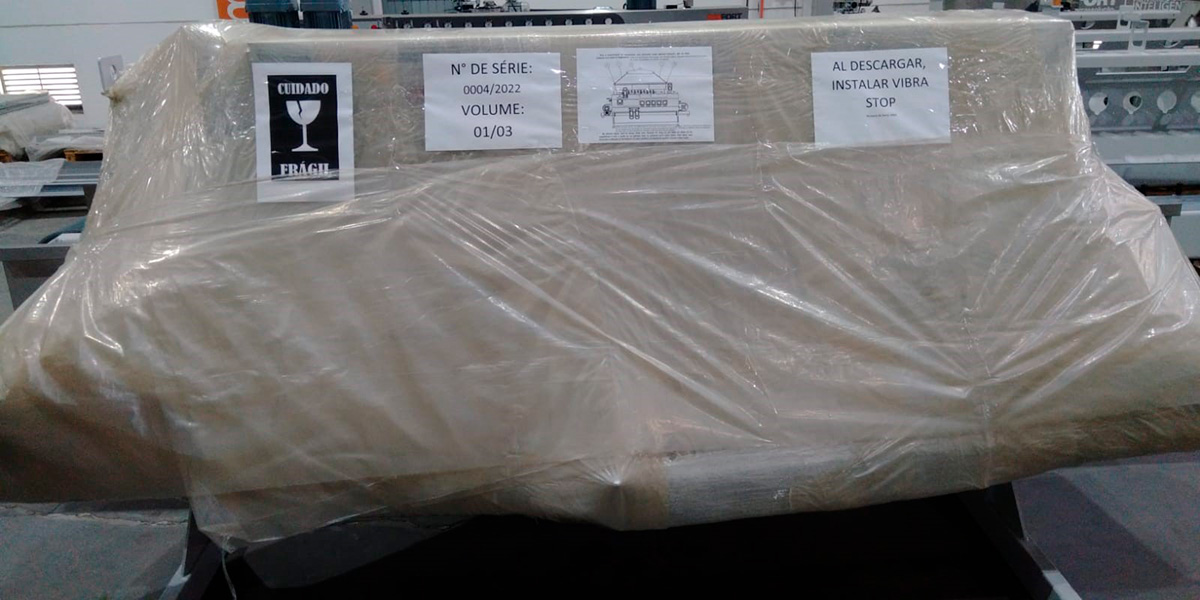

Packaging and delivery

Complete Naked edge polisher for export

| Edge polisher model: Naked | |

|---|---|

| Shipping guidance | Packages cannot be toppled over |

| Packaging specifications | 02 packages wrapped in heat-shrinkable plastic |

| Total cubic measure | 6,04m³ |

| Total net weight | 1118kg |

| Total gross weight | 1150kg |

| Total number of boxes | 02 packages - Dimensions (W x H x D): Package 1/2: 3050 x 1520 x 1250mm – Edge polisher Package 2/2: 1250 x 350 x 550 mm – Infeed and outfeed table |

Other machines

CE-01 counting and packaging machine

CE-02 counting and packaging machine

CE-01 Mini counting and packaging machine

Heat-shrinkable film packaging machine

Automatic orbital Stretch film wrapping machine

Semiautomatic orbital Stretch film wrapping machine ESJ 900

Semiautomatic orbital Stretch film wrapping machine ESJ 1200

Semiautomatic orbital Stretch film wrapping machine ESJ 1600

Semiautomatic orbital Stretch film wrapping machine ESJ 2000

Edge polisher Naked

Cirux bridge Saw

Oblicus 45º Cutting Saw

F400-CS Drilling Machine

F400-T Drilling Machine

F601 drilling machine

05 Axis Machining Center