Why do I need this machine?

Why do I need this machine?

I need to drill medium-complexity pieces;

I have recurring cases of technical assistance due to drilling problems;

High rates of material waste due to improper drilling (rework);

I want to optimize my part marking and drilling processes, reducing production time;

I need to increase my productivity;

I have production batches starting at 30 parts;

If you have any of these problems, talk to us!

F400-T Drilling Machine for Forniture

Prices starting atUSD 84.000,00*

* Check shipping conditions

Product manufactured in accordance with safety standards

100% Brazilian manufacturing

1-year warranty

Higher productivity

Better ergonomics

Quick setup

Quick change chuck without using keys or wrenches

Why choose the F400-T Drilling Machine?

Performs drilling and marking of medium complexity parts of any size;

Average setup of 5 minutes;

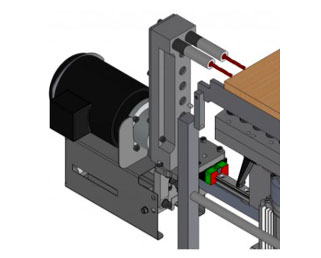

It has a 3rd alignment belt for narrow and long pieces;

Integrated computer, stores up to 5,000 drilling programs;

Quick change of chucks without using keys or wrenches;

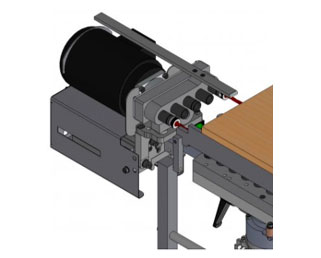

Drill bit-holder cart, Mobile monitor;

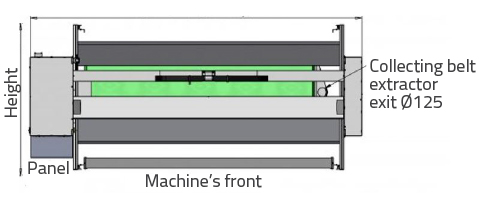

It has a drilling cleaner and a sawdust collecting belt;

LED lighting at the workstation.

Product manufactured in accordance with safety standards

100% Brazilian manufacturing

1-year warranty

Higher productivity

Better ergonomics

Quick setup

Quick change chuck without using keys or wrenches

The F400-T Drilling Machine is the ideal equipment for those looking to unify the drilling and marking stages of parts in the furniture segment, increasing production and reducing errors in this process. The machine is suitable for working on medium-complexity pieces of any size.

Furniture

Technological highlights

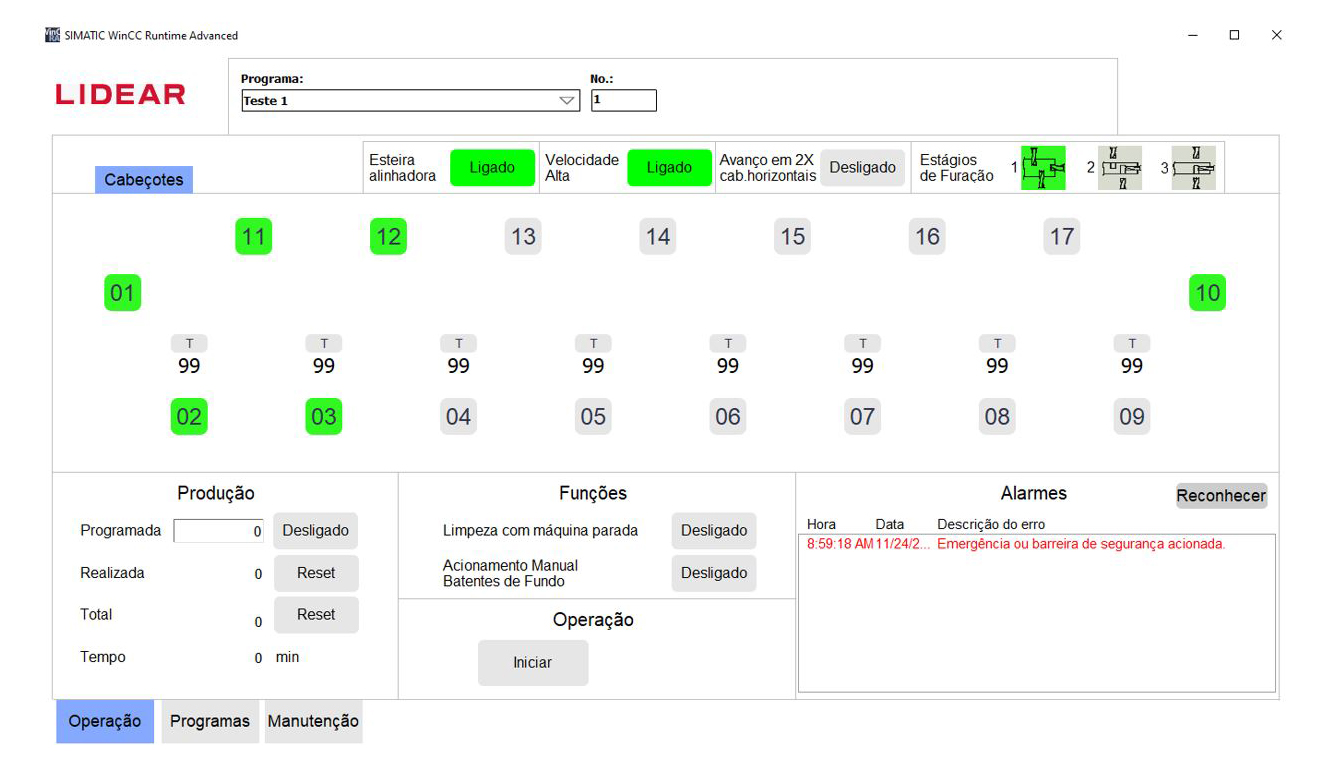

The F400-T drilling machine stores up to 5000 drilling programs and performs medium-complexity jobs in a single operation.

The sawdust collecting belt attached to the machine is also a very important feature, as it helps to reduce the accumulation of waste from the process.

The machine has the smallest setup on the market: simple, fast and without using keys or wrenches!

Before starting the production process, the operator must program the drilling on the machine's computer, selecting the heads, stages and speeds, placing the drill bits in the indicated locations, according to the drawing.

SAFETY IN THE PROCESS - 95% ERRORS REDUCTION:

If the dimensions placed on the digital display is different from the dimensions in the computer, the machine will not start the drilling process.

If these sets move during operation, the machine stops, preventing the process from proceeding incorrectly.

Monitor and drill bit-holder cart

Smart digital displays

The minimum closing between heads is 96mm, making the variety of drillings in a single process even more flexible.

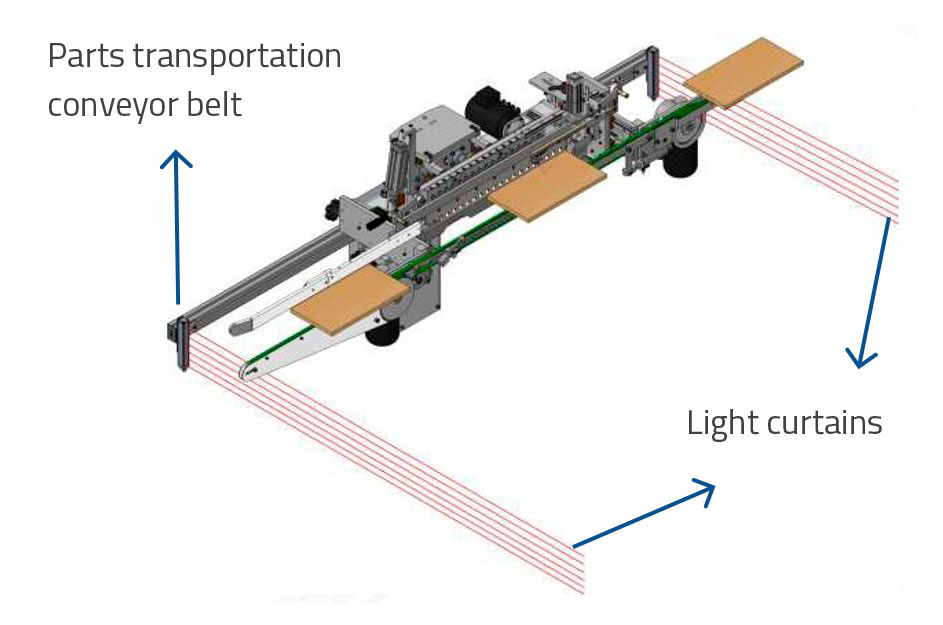

After setting up the machine, the drilling process begins: the parts are fed into the machine’s inlet and transported through the alignment belts, ensuring the correct position of the material to be drilled. The machine has light curtains with sensors that provide greater safety for the operator during the process.

At the end of the process, the processed material passes through the parts cleaner, so that it is clean and ready for the next stage of the process.

Optional extras:

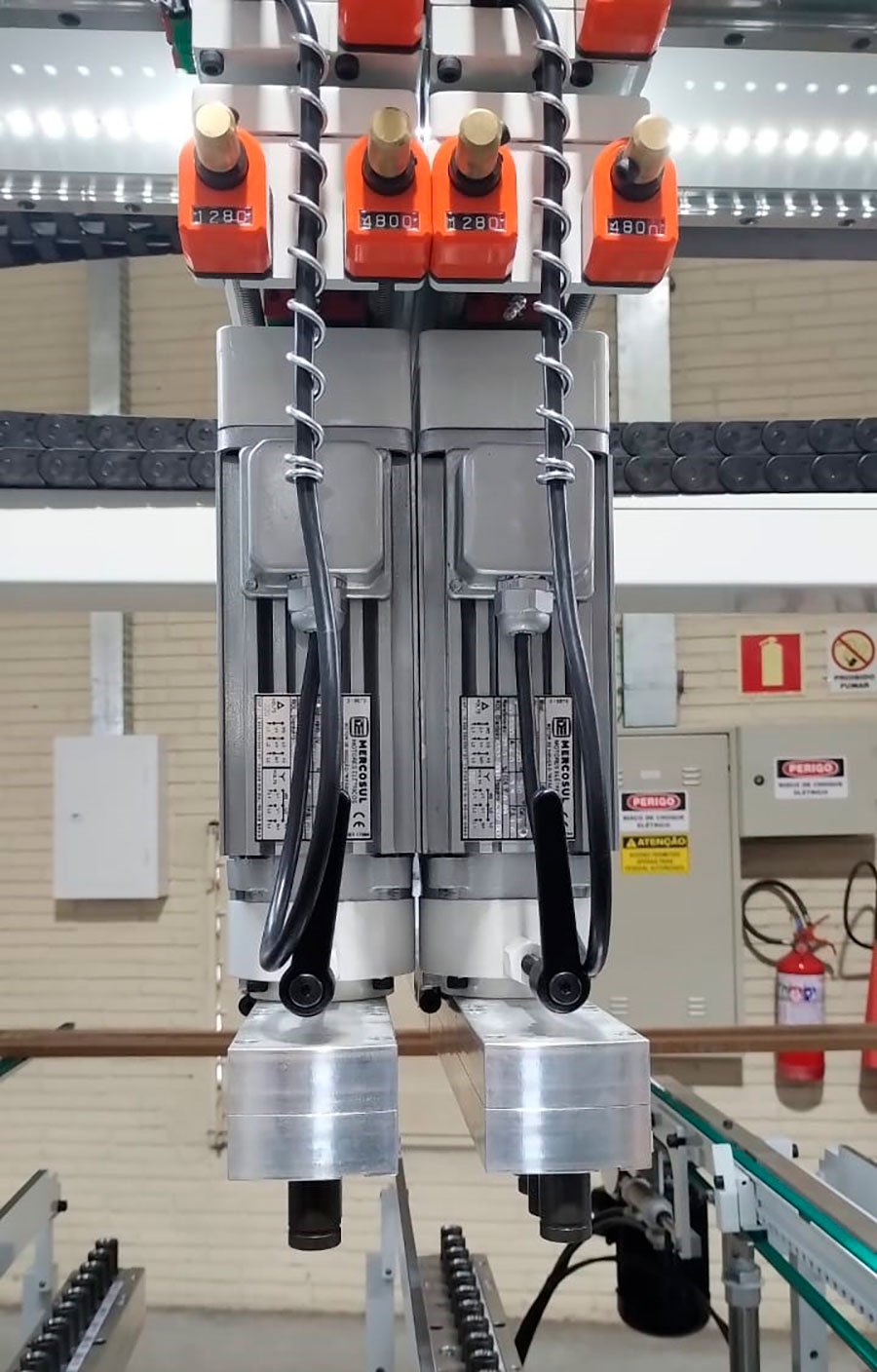

In addition to having sets of horizontal, lower and upper heads, the F400-T drilling machine optionally offers the installation of a set of rear heads with 2 or 5 spindles, enabling the drilling of more complex parts in the same operation.

Set of 2-spindle heads:

Minimum distance between the tip of the part and the first hole: 5mm

Set of 5-spindle heads:

Minimum distance between the tip of the part and the first hole: 53mm

Equipment dimensions

| Dimensions | Measurement unit | F400-T |

|---|---|---|

| Total Length | mm | 4700 |

| Total Width | mm | 2900 |

| Total height | mm | 1900 |

| Net weight | kg | 3000 |

Packaging and delivery

F400-T Complete Drilling Machine for export

| F400-T Drilling Machine | |

|---|---|

| Shipping guidance | Packages cannot be toppled over |

| Packaging specifications | Packages wrapped in stretch film |

| Total cubic measure | (Length x Width x Height) 4,7 x 2,3 x 1,9 = 20,6m³ |

| Total net weight | 3000kg |

| Total gross weight | 3010kg |

| Total number of boxes | 02 Boxes |

Other machines

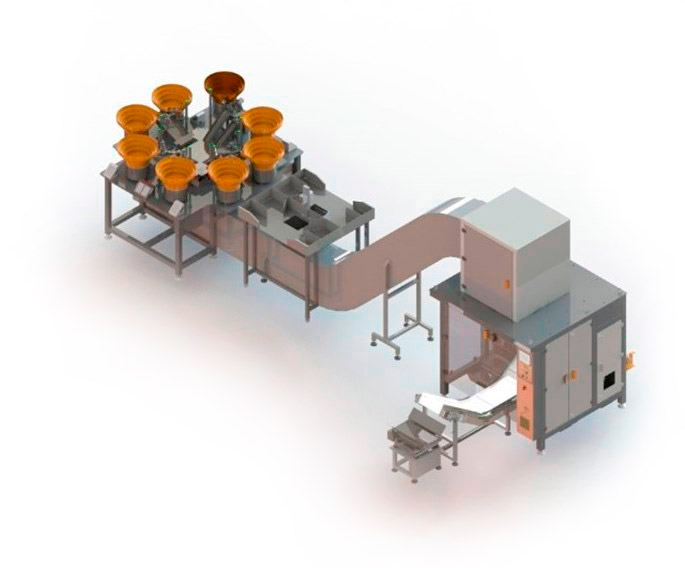

CE-01 counting and packaging machine

CE-02 counting and packaging machine

CE-01 Mini counting and packaging machine

Heat-shrinkable film packaging machine

Automatic orbital Stretch film wrapping machine

Semiautomatic orbital Stretch film wrapping machine ESJ 900

Semiautomatic orbital Stretch film wrapping machine ESJ 1200

Semiautomatic orbital Stretch film wrapping machine ESJ 1600

Semiautomatic orbital Stretch film wrapping machine ESJ 2000

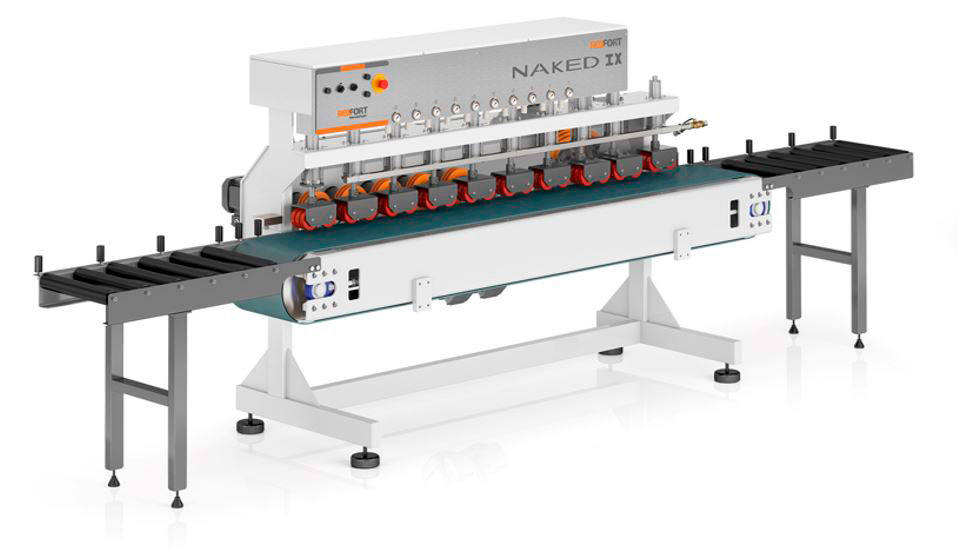

Edge polisher Naked

Cirux bridge Saw

Oblicus 45º Cutting Saw

F400-CS Drilling Machine

F400-T Drilling Machine

F601 drilling machine

05 Axis Machining Center