Why do I need this machine?

Why do I need this machine?

I want to automate my packaging process;

High consumption of materials in the packaging of my product;

Difficulty in standardizing my packaging;

Need to adapt my packaging to e-commerce logistics;

High rate of damaged items due to transport damage;

Low productivity due to manual processes;

Ergonomic failures in the packaging processes.

If you have any of these problems, talk to us!

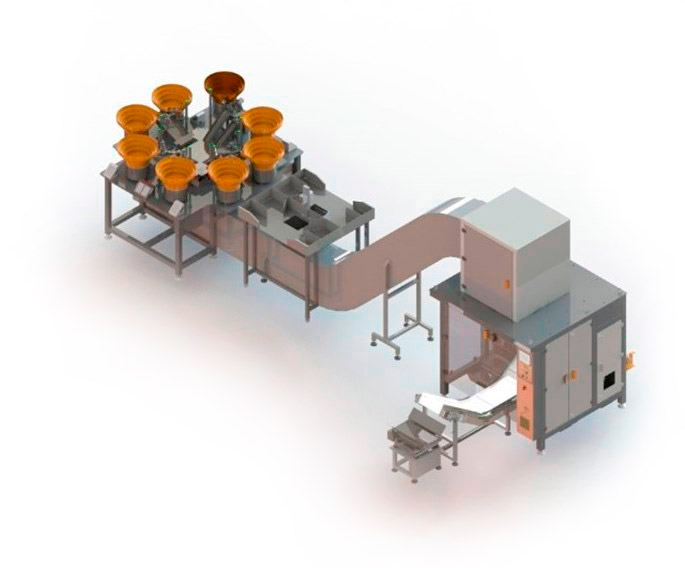

Heat-shrinkable film packaging machine

Prices starting atUSD 41.865,00*

* Check shipping conditions

Product manufactured in accordance with safety standards

1-year warranty

100% Brazilian manufacturing

Ideal for assembled or disassembled items

Packaging with or without additional protection

Does not use compressed air

Higher productivity

Why choose the HEAT-SHRINKABLE FILM PACKAGING MACHINE?

Ideal for assembled or disassembled products;

Packages products with or without box, with or without extra protections;

Greater productivity with less energy consumption;

Protects the product from moisture;

Provides tamperproofing through the total wrapping of the packaging with shrinkable plastic;

Provides better packaging structure;

Reduction of packaging costs;

Productivity increase with the continuous packaging process;

Provides a more adequate packaging for the product's logistical processes;

Applicable to various segments.

Product manufactured in accordance with safety standards

1-year warranty

100% Brazilian manufacturing

Ideal for assembled or disassembled items

Packaging with or without additional protection

Does not use compressed air

Higher productivity

The heat-shrinkable film packaging machine is ideal for packaging assembled or disassembled products from various segments. The PE (polyethylene) packaging is also suitable for long-distance transport and makes the handling and storage of products in stock easier.

Auto parts

Cardboard

Cosmetics

Frames

Logistics

Furniture

Wood industry

Profiles and Aluminium

Textile

Glass

Other segments

Technological highlights

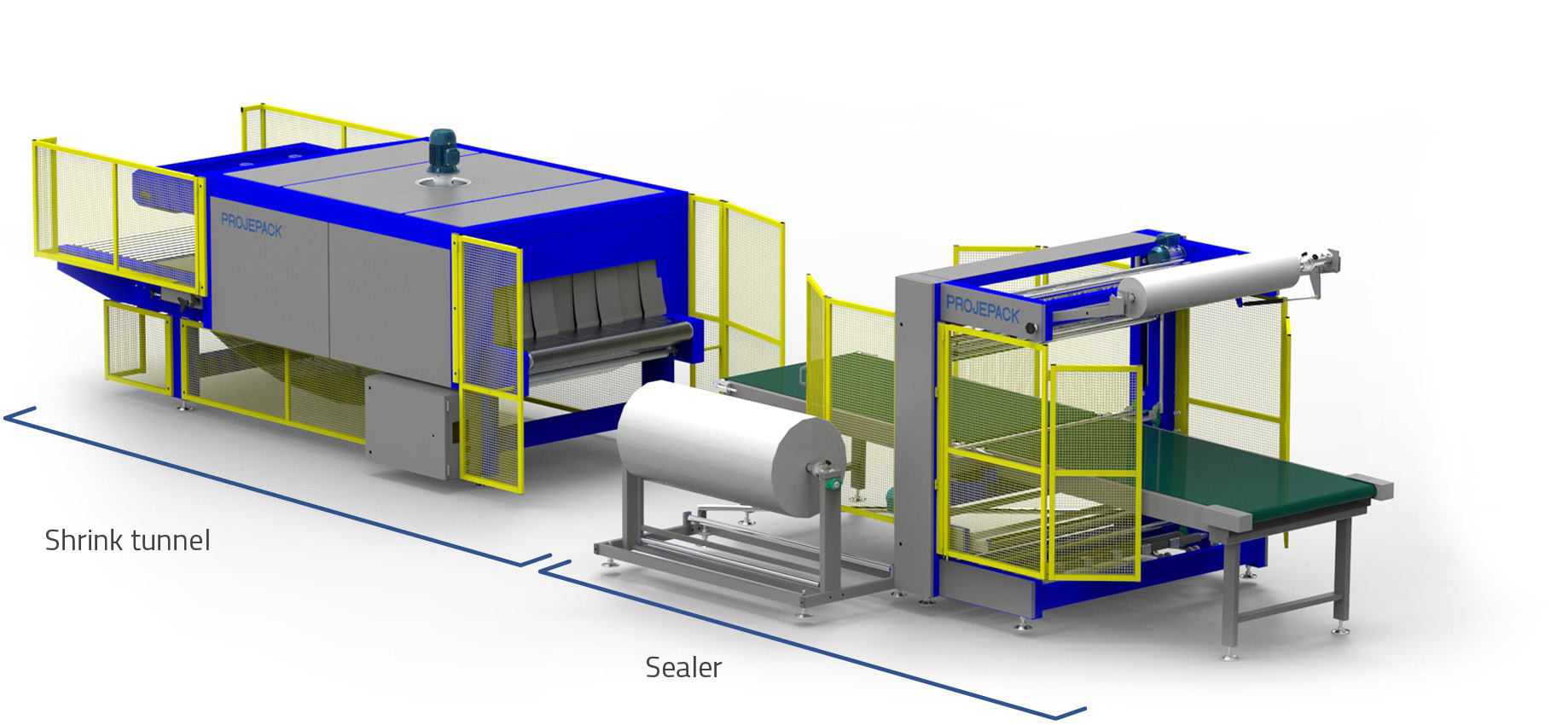

The heat-shrinkable film packaging equipment is composed of a sealer and a shrink tunnel.

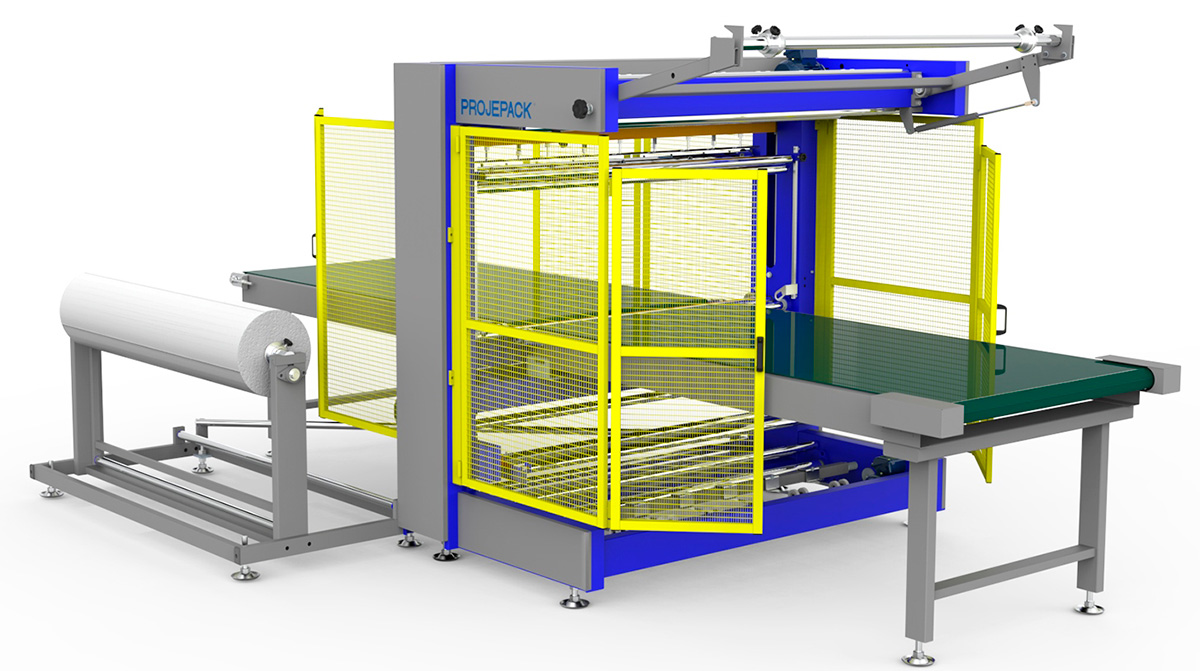

Sealer

The sealer works with POLYETHYLENE plastic film in the packaging system called SLEEVE WRAP which means total closure on the side of the packages by overlapping two films:

The machine operates in an automatic cycle, where the packages are fed by the infeed conveyor. The parts are moved by the conveyor against the film curtain and their passage is detected by an optical sensor, where the sequence of the packaging sealing cycle occurs, subsequently going towards the shrink tunnel.

Technical details of the sealer:

- Electromechanical performance of the sealing/cutting bar, that allows you to regulate its height, optimizing the sealing time of the parts;

- Safety system that prevents the collision of the sealing/cutting bar, with the parts;

- Unwinders with traction on the 2 reels (upper and lower);

- It has sensors to identify the passage of the parts through the sealing/cutting bar to activate it;

- Frequency inverter for the conveyor’s speed control;

- Protection grids on the sealer and on the tunnel, respecting the NR-12 safety standard.

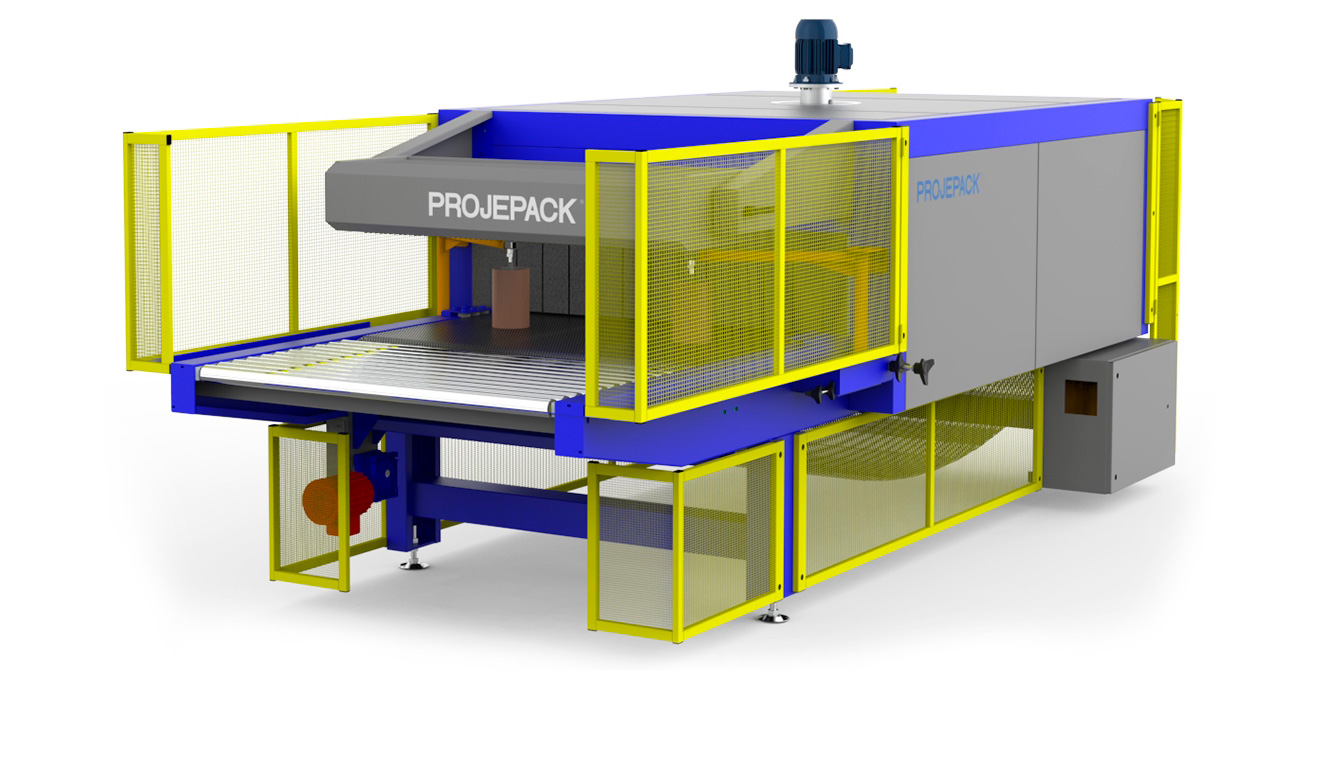

Shrink Tunnel

The shrink tunnel uniformly generates and retains heat inside, while the parts are transported through a steel wire mesh conveyor, performing the shrinkage of the film by blowing heated air over it.

Technical details of the shrink tunnel

- Internally installed hot-air circulation rotor that guarantees an even heat distribution inside the tunnel with a pressurization system to improve efficiency in shrinking speed;

- Thermal insulation with rock wool avoiding the tunnel’s external heating and providing better thermal performance;

- Among its constructive characteristics, its electrical system stands out: it’s protected against motor overload and short-circuit for resistors through fuses, circuit breakers and relays. The power panel protects the resistors;

- Frequency inverter for the conveyor’s speed control;

- Four adjustable feet for leveling;

- The tunnel also has two lateral rolls at its exit. These rolls provide the necessary packaging finish, pressing possible lateral excesses of plastic against the parts (without the use of compressed air);

- Welded carbon steel structure with EPOXY painting;

- Protection grids on the sealer and on the tunnel, respecting the NR-12 safety standard.

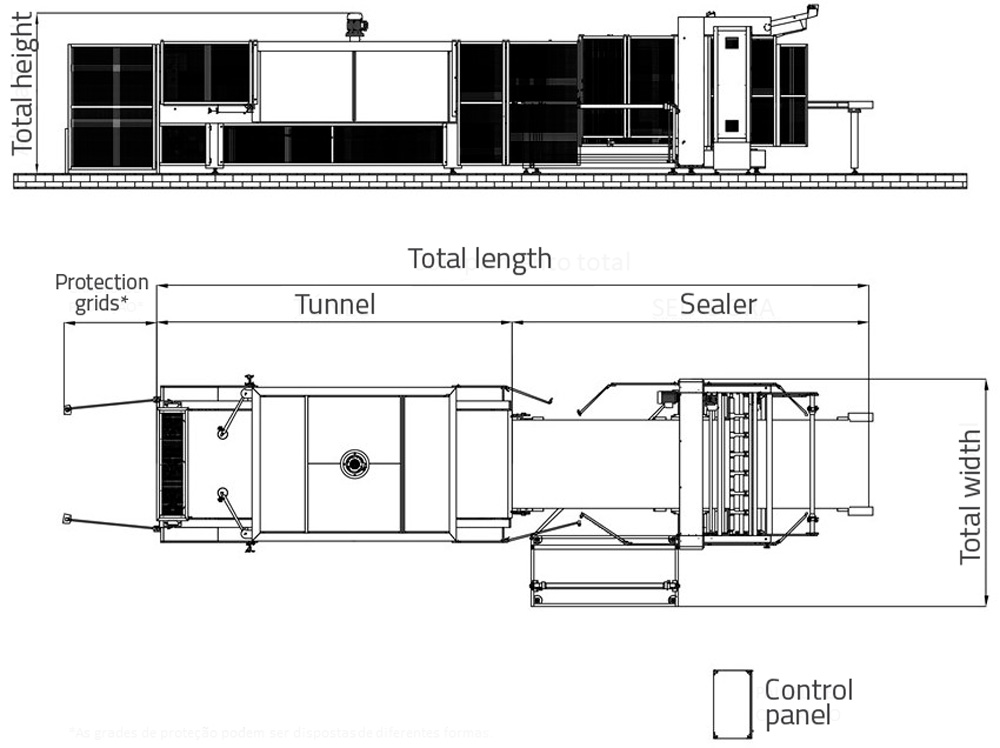

Equipment dimensions

*The protection grids can be arranged in different ways.

| Dimensions (layout) | Set 1 | Set 2 | Set 3 | |

|---|---|---|---|---|

| Total length (mm) | 8000 | 8000 | 8000 | |

| Sealing (mm) | Length | 4000 | 4000 | 4000 |

| Width | 1895 | 2095 | 2295 | |

| Tunnel (mm) | Length | 4000 | 4000 | 4000 |

| Width | 1530 | 1730 | 1930 | |

*Dimensions may vary depending on the project.

Other machines

CE-01 counting and packaging machine

CE-02 counting and packaging machine

CE-01 Mini counting and packaging machine

Heat-shrinkable film packaging machine

Automatic orbital Stretch film wrapping machine

Semiautomatic orbital Stretch film wrapping machine ESJ 900

Semiautomatic orbital Stretch film wrapping machine ESJ 1200

Semiautomatic orbital Stretch film wrapping machine ESJ 1600

Semiautomatic orbital Stretch film wrapping machine ESJ 2000

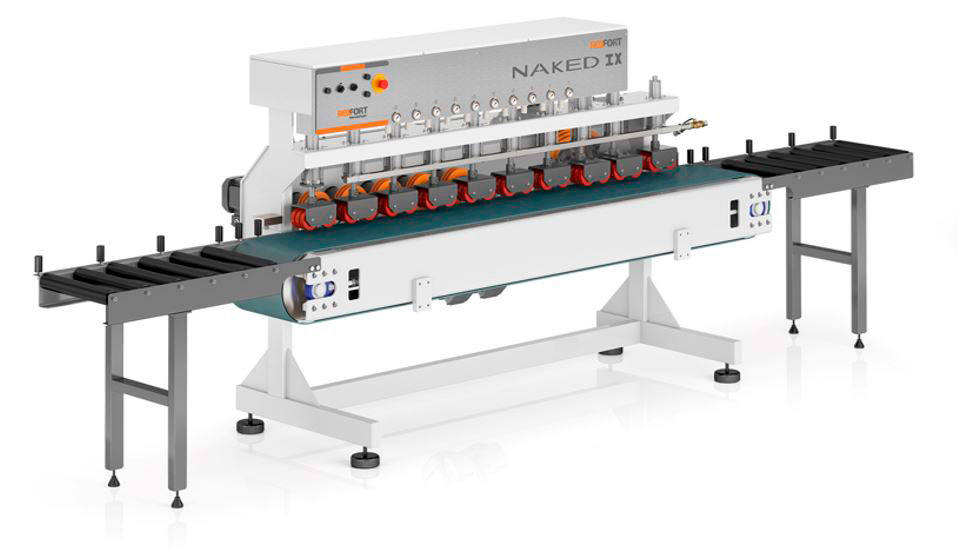

Edge polisher Naked

Cirux bridge Saw

Oblicus 45º Cutting Saw

F400-CS Drilling Machine

F400-T Drilling Machine

F601 drilling machine

05 Axis Machining Center