Why do I need this machine?

Why do I need this machine?

Low productivity due to manual processes;

Difficulty in standardizing the finishing of the pieces;

Crooked 45-degree cuts;

High labor costs;

Inability to effectively control productivity;

Need to reduce delivery time.

If you have any of these problems, talk to us!

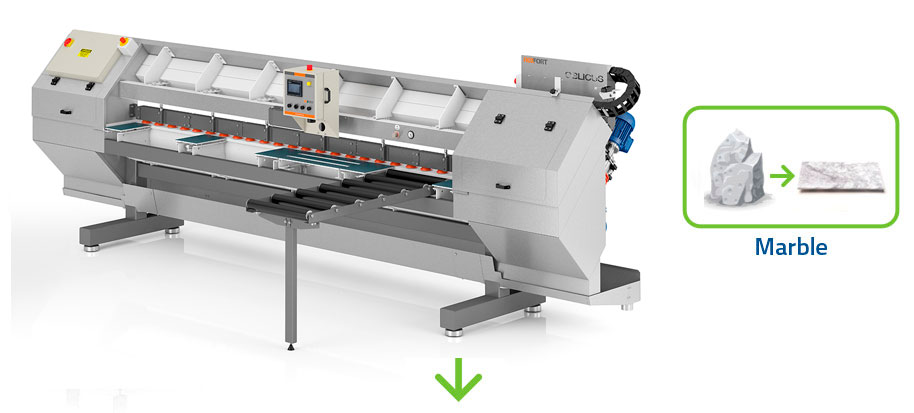

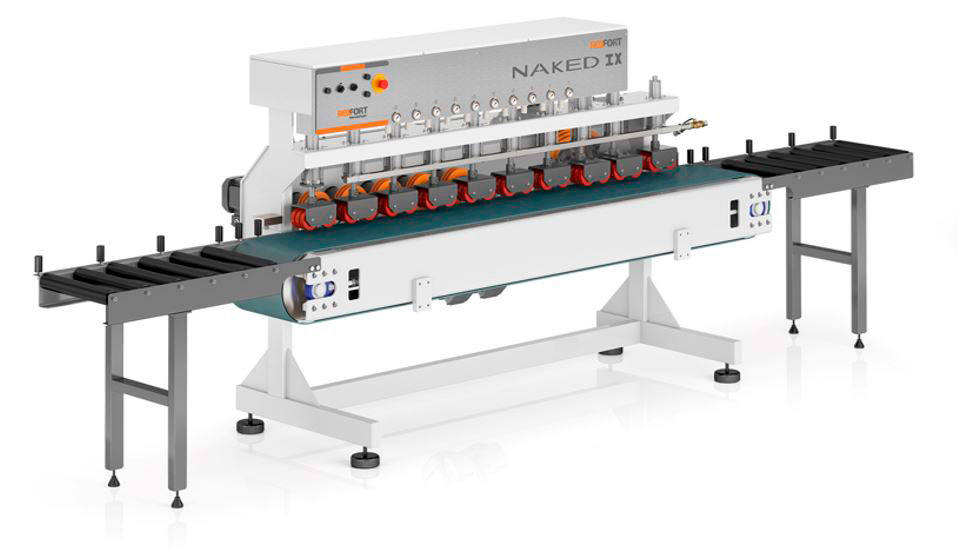

Oblicus 45° Cutting saw

Prices starting atUSD 26.450,00*

* Check shipping conditions

100% Brazilian manufacturing

1-year warranty

Uses compressed air

Higher productivity

Less human interference

Standardization of results

Use recycled water

Why choose the Oblicus 45º Cutting Saw?

Standard, high-level finishing without rework;

Reduction of labor costs;

Works with pieces up to 3200mm wide;

Allows you to work on stones with varying thicknesses;

Cutting group speed control;

Movement system using linear guides;

HMI 4’’

Integrated PLC to store up to 8 recipes

100% Brazilian manufacturing

1-year warranty

Uses compressed air

Higher productivity

Less human interference

Standardization of results

Use recycled water

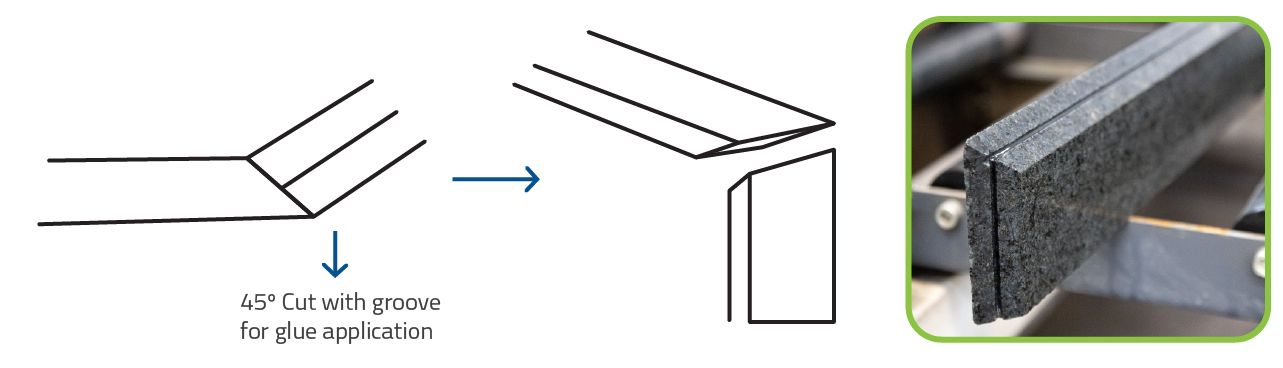

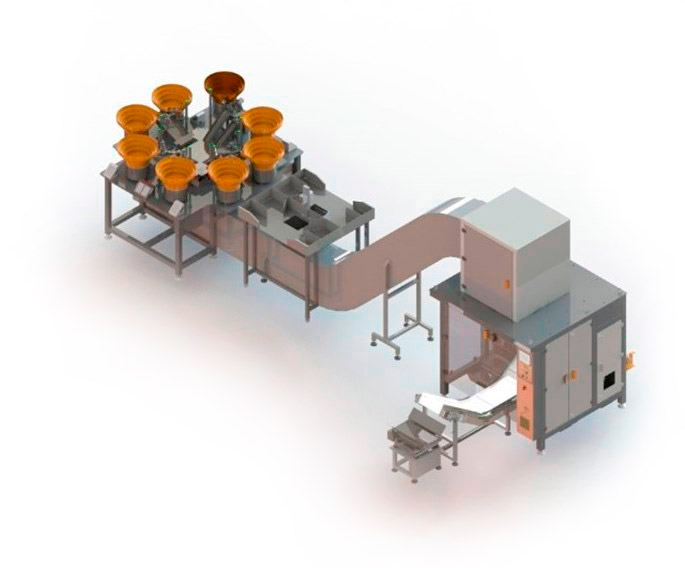

The OBLICUS 45º cutting saw provides a perfect fit of parts, bringing high-quality results. In addition to performing the 45º cutting, the machine performs the roughing out of the piece and the glue groove, improving fixation.

Perfect for the finishes:

Technological highlights

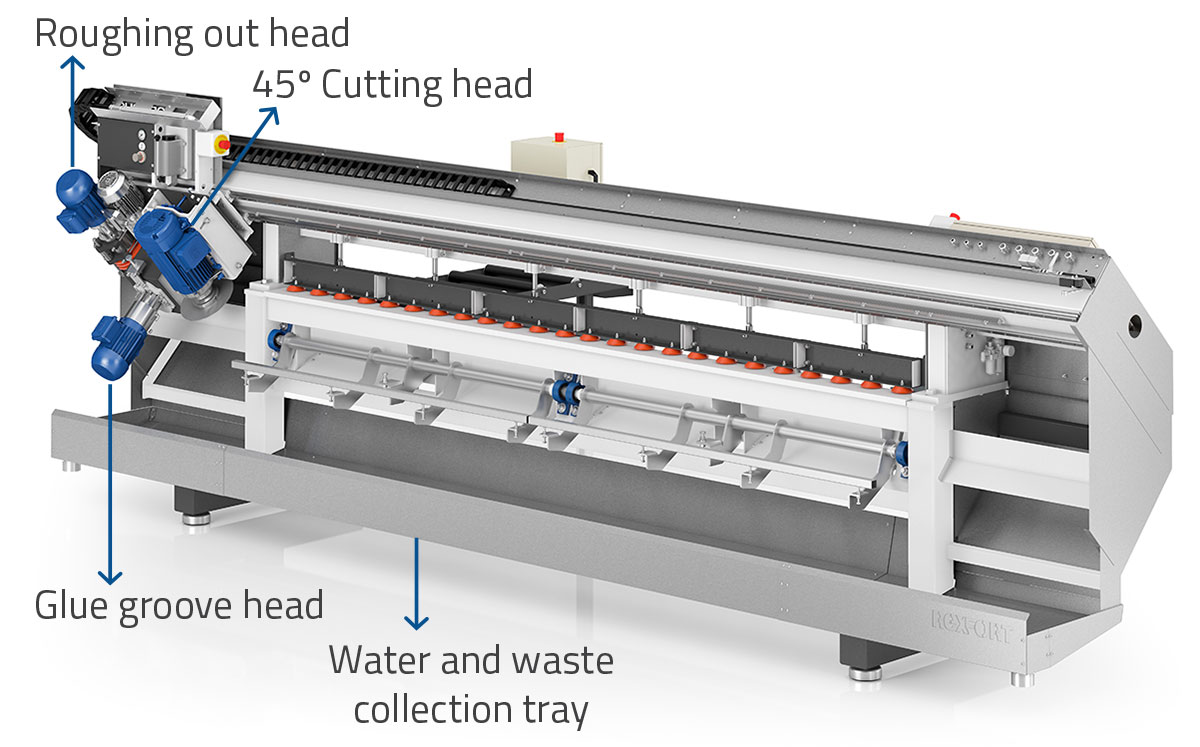

The parts are manually fed into the machine. After activation, the pressing clamps lower and hold the material so that it does not move during the process, ensuring a perfect 45º cut along the entire part, which can measure up to 3200mm in width.

There are 6 pressing clamps that provide total immobility to the pieces. Furthermore, the machine works with 03 heads, distributed according to the diagram below, which move along the part, performing cutting, roughing out and preparing the part for applying glue:

- 01 45º Cutting head

- 01 Roughing out head

- 01 Glue groove head

During the entire process, water is released to cool the abrasives and clean the sludge generated by the wear of the part. To collect water and waste, the equipment contains a lower tray and allows the use of recycled water, if the customer has a decantation tank on their premises.

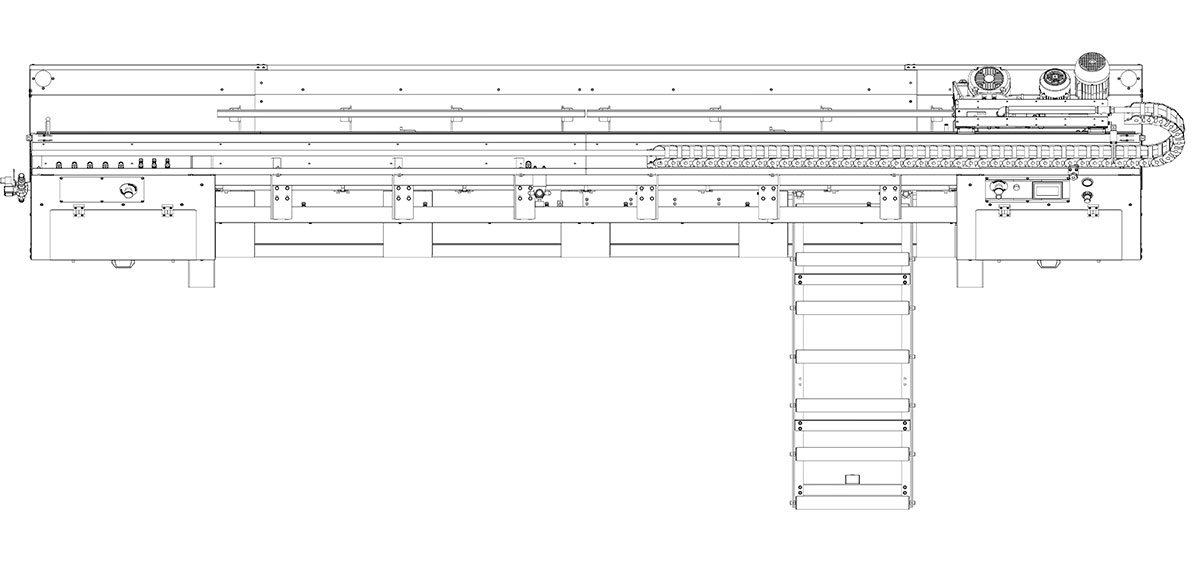

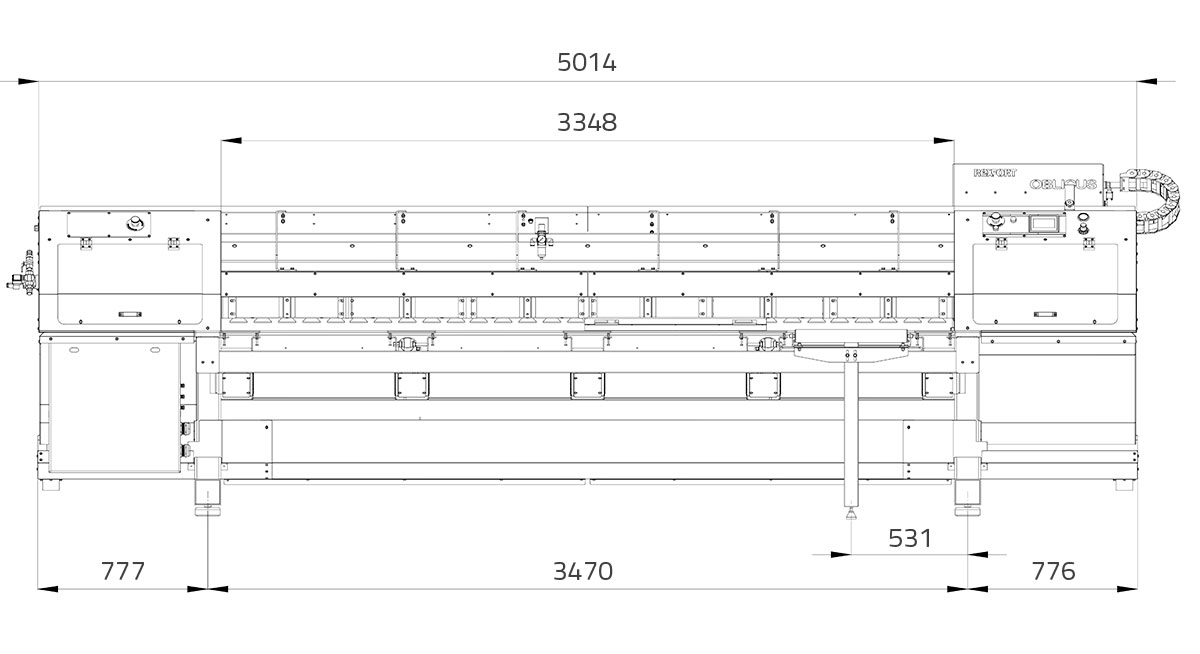

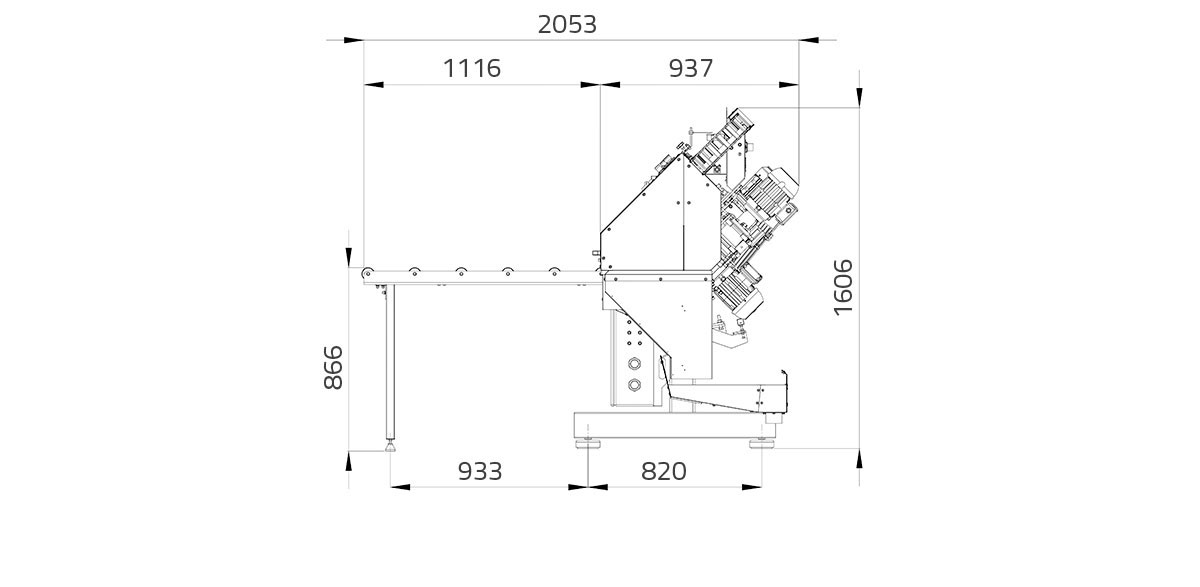

Equipment dimensions

| Length | Width | Height |

|---|---|---|

| 5014 | 2053 | 1606 |

**Dimensions in millimeters

Packaging and delivery

Complete Oblicus 45º Cutting Saw for export

| Oblicus 45º Cutting Saw | |

|---|---|

| Shipping guidance | Packages cannot be toppled over |

| Packaging specifications | 2 Packages wrapped in stretch film |

| Total cubic measure | 9,62m³ |

| Total net weight | 1200 kg |

| Total gross weight | 1250 kg |

| Total number of boxes | 02 Boxes - Dimensions (Width x Height x Length) Box 1/2: 1080 x 1632 x 5365 mm Box 2/2: 565 x 200 x 1450 mm |

Other machines

CE-01 counting and packaging machine

CE-02 counting and packaging machine

CE-01 Mini counting and packaging machine

Heat-shrinkable film packaging machine

Automatic orbital Stretch film wrapping machine

Semiautomatic orbital Stretch film wrapping machine ESJ 900

Semiautomatic orbital Stretch film wrapping machine ESJ 1200

Semiautomatic orbital Stretch film wrapping machine ESJ 1600

Semiautomatic orbital Stretch film wrapping machine ESJ 2000

Edge polisher Naked

Cirux bridge Saw

Oblicus 45º Cutting Saw

F400-CS Drilling Machine

F400-T Drilling Machine

F601 drilling machine

05 Axis Machining Center